Creativity

What is value engineering?

Value engineering is the art of maximizing product profit by balancing value adding product features and cost by engineering creativity.

The term value engineering origins from General Electric that were challenged on resources and raw materials during World War II. In the search of substitutes – it was found that cost and and quality was improved – and was turned into a systematic process – called “value analysis”.

VAVE

Value engineering & value analysis

What is "value engineering" and "value analysis" and what is the difference?

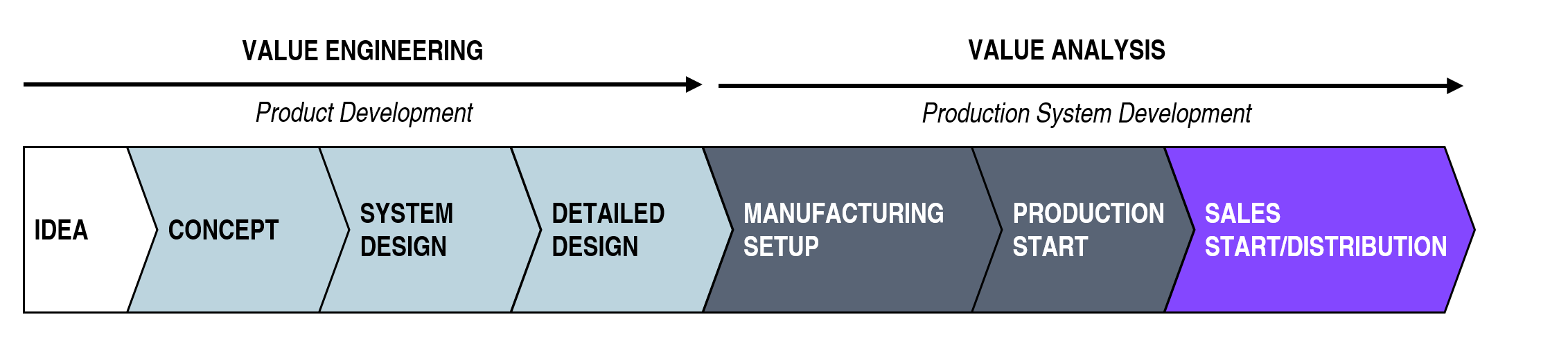

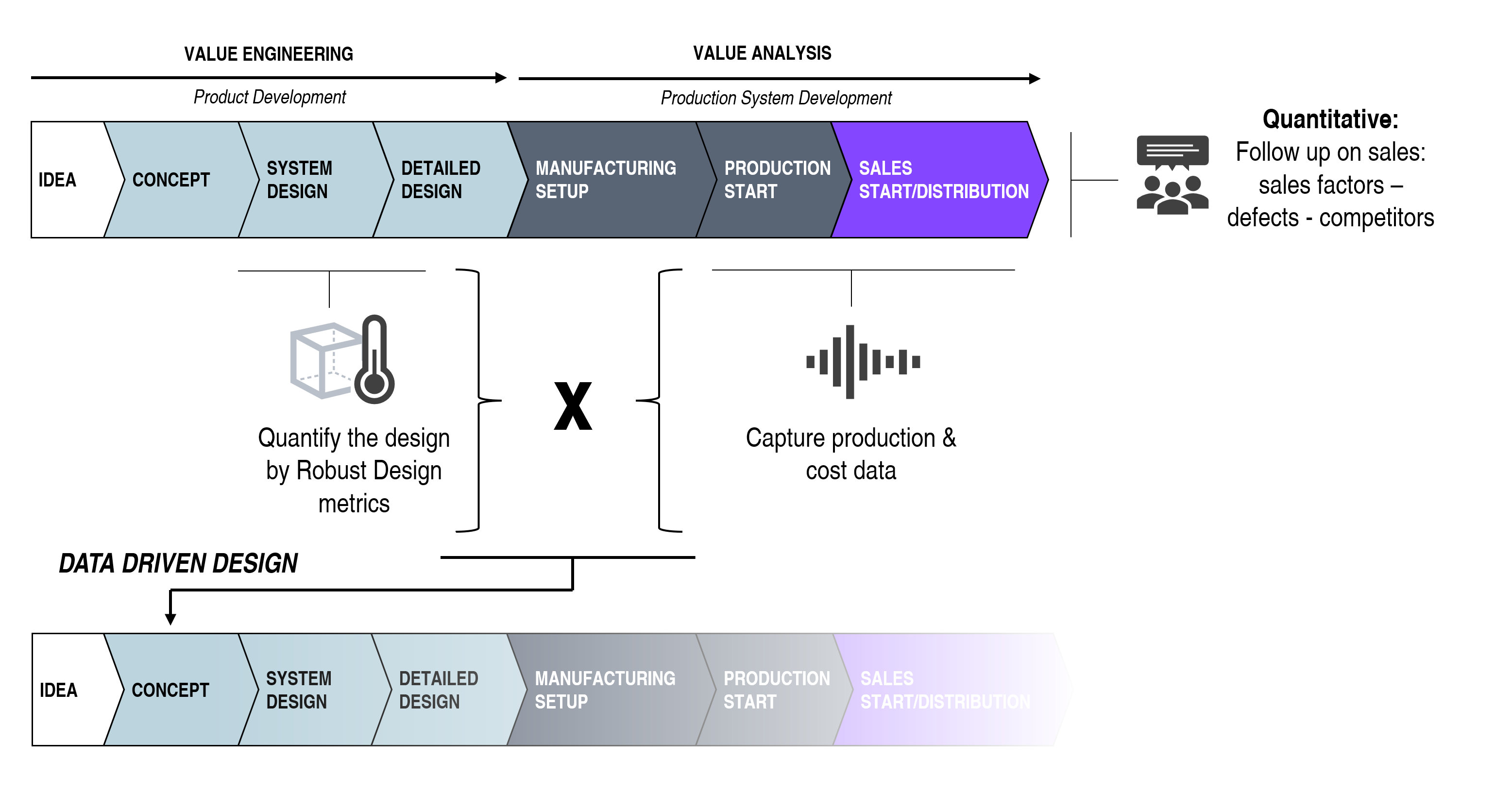

At Toyota, value engineering is used as a term for balancing functional requirements and cost. The term value engineering is typically used at the product development stage/department and is called value analysis when handed over to production/mass production.

The methods are to be used from day 1 – in the early planning/concept phase of a product development project – to ensure that the product has the right value-for-money.

What?

The difference between value engineering and value analysis

Toyota distinguish between value engineering and value analysis by who and when value adding activities are done.

Value Engineering (VE) is typically performed in the product development department and Value Analysis (VA) is performed in the production department. At Toyota, VE is performed in the TPD (Toyota Product Development (System)) and VA in the TPS (Toyota Production System) [1].

Why is Value Engineering Important?

Benchmarks from Toyota show that 95% of profit is set in the product development phase [1]. Meaning that only a few percent can be optimized after design freeze. The ability to enrich the quality and value of design is hence really the important driver for companies selling physical products.

Take Apple for example – they do not make a profit from optimized production sites – it is all outsourced to sub-suppliers. The value is in the design information and the know-how for how to create new designs.

Robust Design methods are key to the establishment of designs of high value that can be sourced/produced at low cost.

[1]: The Secret Behind the Success of Toyota: How the Original Chief Engineer System Works to Generate Most of the Product Value and Profit, Takao Sakai, Independently Published, 3 Mar 2018

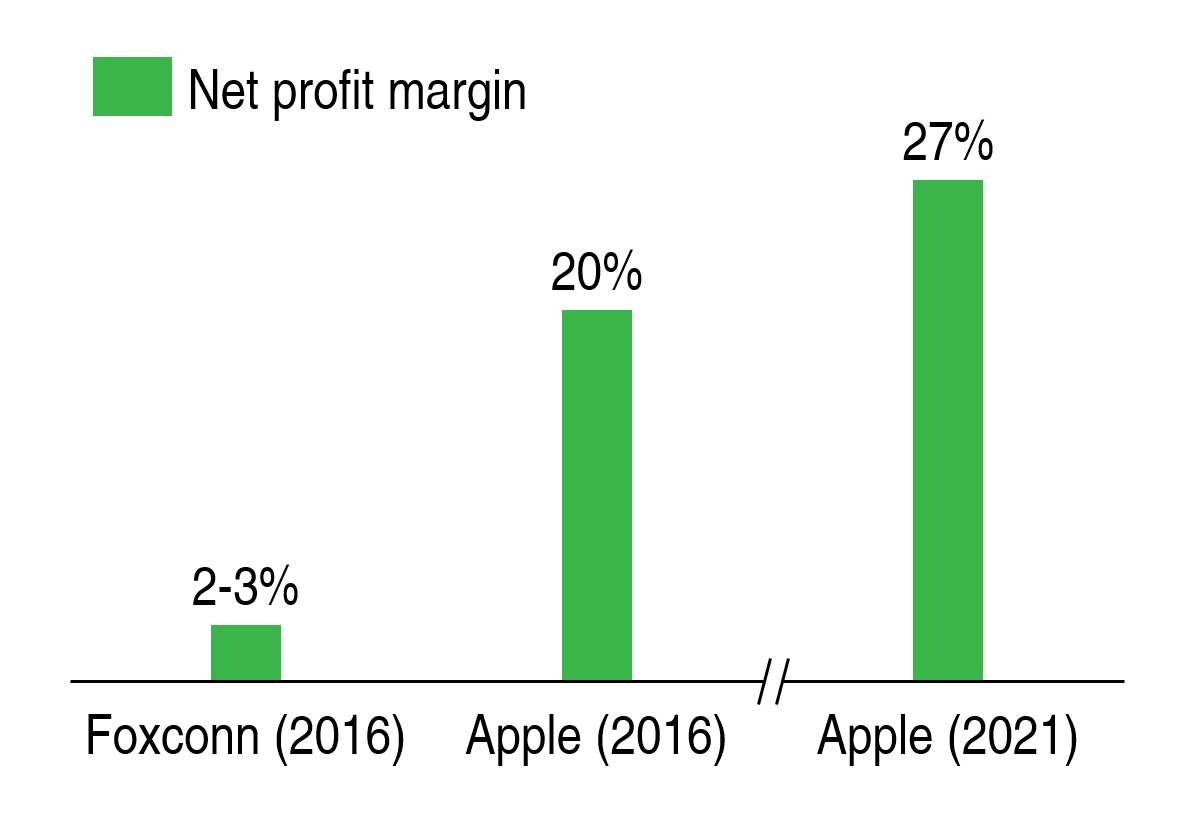

Net Profit Margin [%], Foxconn vs. Apple (2016)

Foxconn, the assembler, makes significantly less profit than Apple (the designer). The year 2016 is used as a reference year. The growth only increased for Apple when compared to the year 2021.

Types of companies

Wonder why Apple is a money maker?

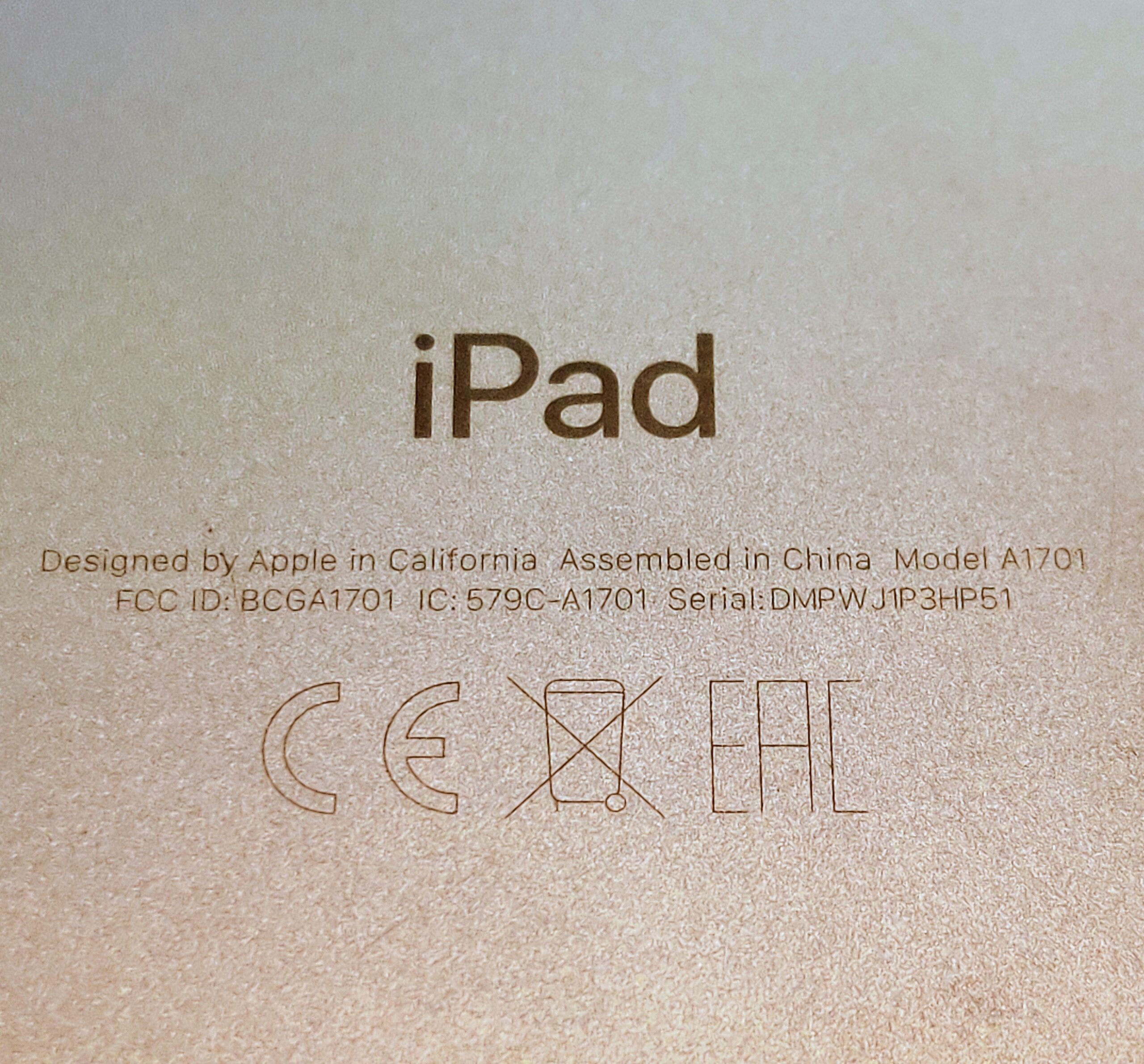

Seen the back of an Apple product? "Designed by Apple in California. Assembled in China" (The majority of the profit is in the design).

Interface design

Predictable design

How to design mechanical interfaces right first time to ensure maximum value?

What are the elements of value engineering?

Create products that sells!

Maximize price (product quality and performance) by Robust design. Minimize cost by Robust Design.

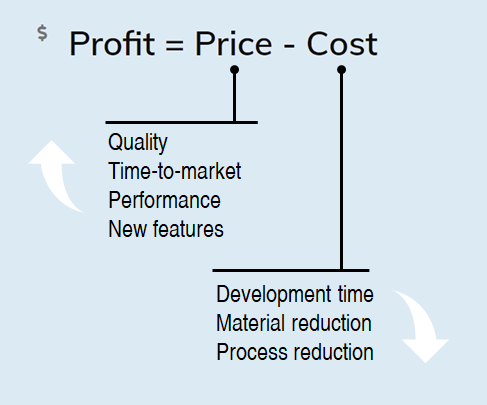

Profit = price - cost

Let's dig into the simple equation

The objective of value engineering is to ensure maximum profit. Profit is determined by the price (sales price) minus the cost (spend used to realize the product).

Hence, to maximize profit; price needs to go up and cost needs to go down.

To excel in value engineering research and data are key elements.

Research/development: e.g., development of new cost-cutting production processes, materials, or way-of-working (imagine the efficiency cost saving by the introduction of PC’s/CAD programs to create 2D part drawings). Development of new technologies for improved product value/user experience – e.g., development of new materials for less weight or increased strength. Robust Design processes are often an unexplored area for many companies to yield improvement. Robust Design can be used to reduce development time, reduce cost and improve product features.

Data: to excel in cost planning – data is the key to provide insights on cost-cutting potentials. Collection of production, purchase, and user data aid to benchmark the current state and sets the bar for improvements. Robust Design metrics can be used to link design with business data to identify potentials.

Mechanical engineers

What do value engineers do?

Value engineers work with improving products to lower cost or improve the product so that the product price can be increased - to maximize profit or stay competitive.

PRICE – examples of levers to increase the price

- Product features (new product features)/competitiveness

- Customization [Robust platform design supports next level product customization]

- Quality

- Delivery/availability

Price is set by product competitiveness in the market.

RD8 Robust Engineering System: RES supports ideal embedment of new features/technologies and time-to-quality (hereby quality and delivery/availability)

COST – examples of levers to decrease cost

- Change of fabrication method

- Change of material

- Reduction of waste/scrap

- Volume consolidation

Robust Design methods are powerful tools to cost reductions – learn more.

Price is set. As price is based on product scope/set of features, expected quality, user segments, etc., this is a set variable.

The ability to deliver the expected features at the right quality at the lowest cost is the art of value engineering.

As the price is set – the ability to perform “target costing” (projecting a design with low cost) and deliver just that is the core of Value Engineering.

Value Engineering as a process

Powered by Robust Design

| STEP 1 | Quantify design information Robust Design metrics links a set of objective measures to design information. This is key for benchmarking and to point out improvement areas. |

| STEP 2 | Capture production and cost data Capture cost, value adding processes.Harvest data from operations (scrap data, cycle times, bottle necks, etc.) and supply chain (part prices, material prices, shipping, logistics, etc.) |

| STEP 3 | Capture sales and customer data Identify which features drives sales and which add value. Identify potential defects and improvement areas. Identify competitors and how their features are performing. |

| STEP 4 | Link design information and data Utilize data! Combine design information – by linking robust design metrics to captured data (illustrated by an “x” in the figure). Create transparency for chief engineers by databases & live dashboards/tools. |

| STEP 5 | Data driven design Use know-how, metrics and robust design methods to draw the first concept sketches/lines with the exact balance of information (in the concept/planning phase). Determine production processes, material selections, assembly-flow/strategy based on trustworthy measures to achieve ideal value and cost for the product. |

Target Costing & Cost Planning

Powered by Robust Design

The ability to create and synthesize a design with low cost with a given set of requirements with low risk is the key target for Value Engineering.

Setup for successful/accurate target costing

- Guiding design metrics

- Link between design, product performance and company repository

- Company repository (database) consisting of:

- Part know-how (cost, weight, material, etc. – to be able to drive quantitative improvements)

- Accumulated chief engineer knowledge (management/documentation of know-how)

- Accumulated project knowledge (continuous improvements)

- Technology know-how

- Production know-how (capabilities and cost relations – feedback loops)

Assets for cost reduction cost planning

- Data driven design process and targets (robust design metrics)

- “Design drivers” – applying company know-how and cost drivers driven by physics (e.g. weight)

- Concurrent design / integrated product development

- A technology roadmap in place – planning and research for:

- new cost reduction technologies or

- technologies than enhance product value (Price)

- Kaizen – creativity to lift standards (engineering talents)

Balancing the unknown

Product development fact

In the product development phase: the "unknown" is bigger than the "known". Utilize data/robust design metrics to minimize risk for wrong cost setting.