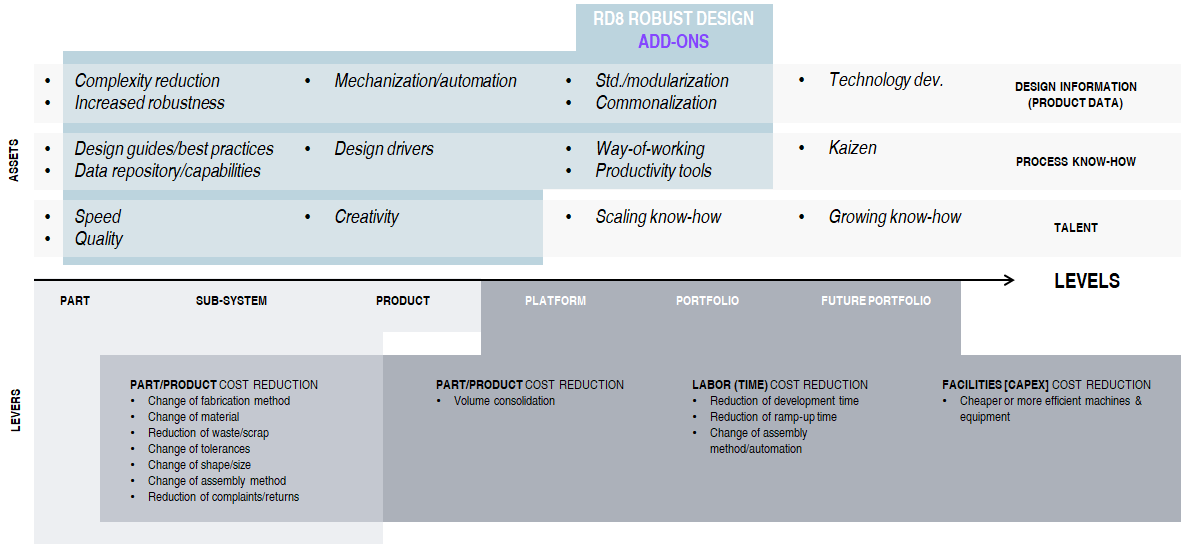

Next level cost reduction powered by Robust Design

Illustration of cost reduction levers and assets/efforts to drive cost reductions – in relation to product levels.

Assets: initiatives/efforts to enable levers.

Levers: drivers for cost reductions on the balance sheet.

Levels: indication of the effect of a cost reduction asset. Complexity reduction on a single part has less impact than if the complexity reduction is scaled to a product platform or portfolio by standardization.

LEVELS

PART – Single components

SUB-SYSTEMS – E.g. a gearbox unit in a car

PRODUCT – Assembly of parts and/or sub-systems

PLATFORM – A technical platform to configure products – e.g. a Volkswagen Golf: Golf, Golf GTI, GTE, Golf eHybrid, Golf Variant. In fact, almost all VWs are based on the same platform – meaning that both a VW UP! (small car) and a VW Passat (medium/large sized car) are two different configured versions of the same car – branded as different products.

PORTFOLIO – Range of products – e.g. BMW’s 100-series, 200-series, … 700-series, …

FUTURE PORTFOLIO – The future product range

COST REDUCTION LEVERS

PART/PRODUCT COST REDUCTION

- Change of fabrication method (e.g., CNC to injection molding)

- Change of material (e.g., steel to plastic)

- Reduction of waste/scrap (elimination of waste)

- Change of tolerances (e.g., enables faster process times, low-cost suppliers, lower cost fabrication methods)

- Change of shape/size (e.g., reduction of weight/material usage)

- Change of assembly method (e.g., manual to semi-automatic assembly)

- Reduction of complaints/returns (e.g., reduction of claims handling, repair, replacement products)

- Volume consolidation (read more about scaling effects)

LABOR (TIME) COST REDUCTION

- Reduction of development time (read more)

- Reduction of ramp-up time (e.g., concurrent engineering and reduction of engineering detours)

- Change of assembly method/automation (e.g., enablement of fully automatic production or maximizing of operator time)

FACILITIES [CAPEX] COST REDUCTION

- Cheaper or more efficient machines & equipment (e.g., investment in low energy equipment)

DESIGN INFORMATION ASSETS

Efforts to drive cost reductions/levers in general and boosted by Robust Design.

DESIGN INFORMATION ASSETS

COMPLEXITY REDUCTION – Simplification by kinematic interface design – on a part, product, and platform level – reduces requirements and component cost (reduction of overengineering).

INCREASED ROBUSTNESS – On a part, sub-system, product, and platform level – enabling low-cost fabrication methods, low-cost materials, less QA cost, reduction of waste, automated assembly, and fewer product complaints. See an example of robust interface design (60% reduction of complexity).

MECHANIZATION/AUTOMATION – Automation of production and assembly reduces the labor cost.

STANDARDIZATION & MODULARIZATION – Drives volume consolidation and hence cost reductions.

COMMONALIZATION – Reuse of design information across products.

TECHNOLOGY DEVELOPMENT – Development of new technologies to enrich product design – e.g., by CAD, CAE, Machine Learning, Artificial Intelligence (AI).

PROCESS KNOW-HOW ASSETS

Design guides/best practices – Ensures quality and reduces development time.

Data repository/capabilities – By using “company repository”/data (see Value Engineering) in new designs ensures that previous failures are not repeated and that company know-how is utilized for new designs – enhances the probability of right-first-time designs (reduction of development time) and enhances the quality.

Design drivers – Guiding principles for product development lowers product/part cost and development time – e.g., for a car, a design driver could be “low weight” as low weight drives less material usage (= low cost), good fuel economy, small motor (= low cost), fast acceleration (sporty feel), … Each product possesses its own unique set of design drivers – driven by physics and product requirements. Design drivers are an essential part of RD8 new product development approach.

Way-of-working – A data-driven way of working reduces development time and increases quality.

Productivity tools – Development of new technologies to enrich product design – e.g., development of MatLab scripts, sophisticated AI algorithms, or even their own CAD/PLM systems to save time and increase product quality.

Kaizen – Increase standards from a stable level to an enhanced/higher level.

TALENT ASSETS (PEOPLE ASSETS)

Speed – Some engineers are faster than others – saving development time (learn how to enhance the speed of engineering professionals by applying a robust way of working).

Quality – Some engineers/designers deliver better quality than others (learn more about how to yield most of all individuals by Robust Design talent development programs).

Creativity – Applying great brains to perform Kaizen work (adding Robust Design methods yield new fields of creativity) – to increase product performance or to develop cost reduction mitigations.

Scaling know-how – Applying/scaling new know-how into new standards & developing other individuals and teams – multiplying cost reduction know-how to the organization (reduces development time and/or product cost).

Growing know-how – Development of new know-how (experience, testing, research, development, …) to reduce cost or increase the product price.

Term

OPEX

Operational expenses - cost used to keep the product production rolling. Labor cost, ongoing material cost, etc.

Term

CAPEX

Capital investment expenses - cost used to get the product production rolling: investment in machines, equipment, buildings, tooling, prototypes.

Abbreviation

CAD

Computer Aided Design

Abbreviation

CAE

Computer-Aided Engineering - in example Finite Element Analysis (FEA) or Computational Fluid Dynamics (CFD)

Abbreviation

PLM

Product Lifecycle Management