ROBUST DESIGN

Design for Quality, Delivery and Cost

We believe that Robust Design is key for "time-to-quality" and "right-first-time design". We know what good looks like! Upgrade your product development with the RD8 robust engineering system. The RD8 robust engineering system is an insurance and quality management system for your product design approach - enabling transparency and objective design metrics lowering the probability of product launch issues and risk of development detours.

Quality management system for R&D – ensure quality of design information

Leading indicators for

RD8 Ecosystem implementation

RD8 Ecosystem supports being best-in-class when working with professional product development and enables R&D organizations to work smarter.

GREENER. SIMPLER. FASTER. SMARTER.

The RD8 way of working aims to develop and produce physical products in a greener, simpler, faster, and smarter way.

Example

Greener

Sustainability

CHANGE OF COMPONENTS FROM VIRGIN TO RECYCLED MATERIALS

Example

Simpler

Complexity reduction

COST REDUCTION

Example

Faster

Engineering productivity

REDUCTION DEVELOPMENT TIME

Example

Smarter

Product performance

IMPROVED SEALING FORCE BETWEEN COMPONENTS

Typical

Embed Robust Design in product development

Typical steps for integration of robust design into R&D development process and culture.

Planning

1-4 weeks

Talent development

See training programs

Toolbox

Tailoring tools to company settings

Processes

Integration of way-of-working into development process.

Mangement

Embed Robust Design metrics as a competitive edge

Project application

Application of Robust Design methods on new or redesign projects

- Mobilization of team

- Setting governance

- Timeline

- Robust Design training (see training levels and profiles)

- Project support (application of training to projects)

- Coaching for project leads/project managers/chief engineers

- Culture drivers & ambassadors

- Application of tools/learning to use tools

- Feedback loops & links to data-models

- Tailoring of tools to company specific settings

- Identification of projects/products

- Improve product portfolio robustness: redesign or design of new products

- Alignment with agile/stage gate processes/NPI process

- Alignment with roles & responsibilities

- Continuous improvements workflows

- Alignment with modular setup/standards

- Alignment with workflows/meeting structures/reporting structure

- Active use of Robust Design metrics: portfolio management & roadmap

- Alignment with data analytics/PLM systems/production data/sales data/customer data

- Transparency – visual management

- Reporting/KPIs/management playbook

HOW TO ACHIEVE RESULTS?

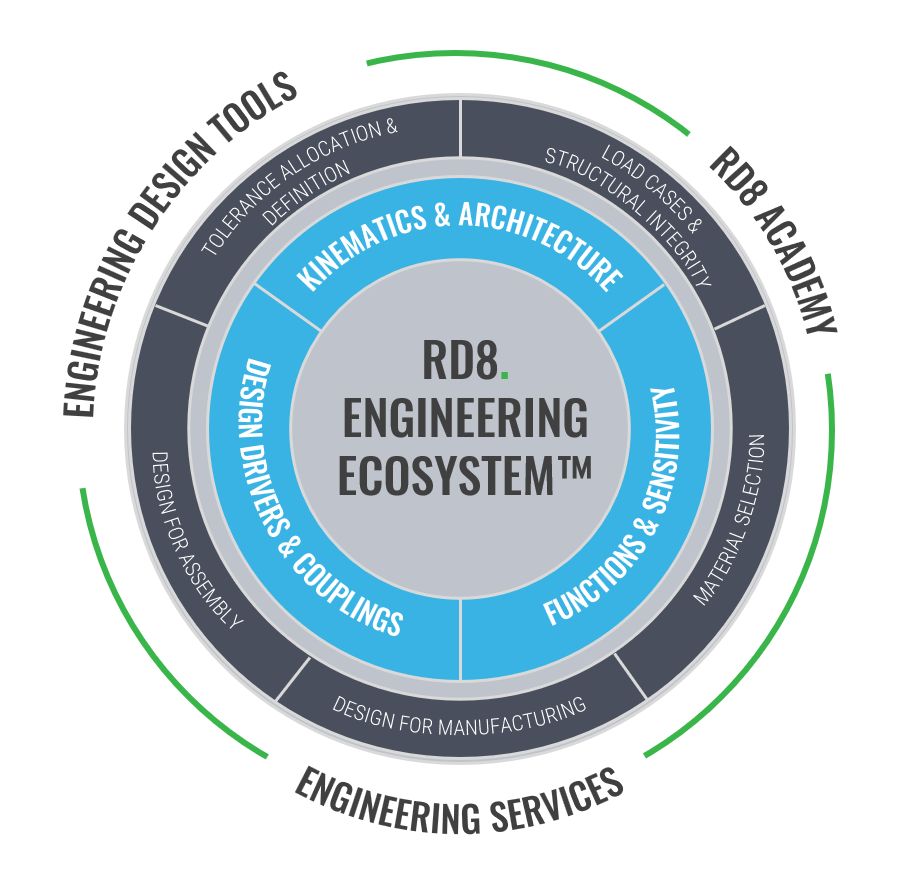

To enable organizations to realize the benefits of Robust Design, we introduce the RD8 Engineering Ecosystem. A resolution to link Robust Design tools, processes, governance and people together to enhance the robust way of working. It is an R&D upgrade.

Create an innovation factory!

Challenge requirements and specifications. Set long term goals. Lead the market. Be data-driven. Set the standard now and going forward.

Elements are:

A scalable engineering toolbox

RD8 Academy – development of teams, individuals, and leaders.

Engineering Services – To solve hands on solutions and implement the way of working.

RD8 RES results in sustainable solutions; by changing the way designers design products and components and how they are sourced, manufactured, and put together!

Greener sustainability

Design for green components, manufacturing, use and disposal

Simpler complexity reduction

Simpler part drawings - fewer tolerances and less strict tolerances.

Faster engineering productivity

A systematic and data driven approach to product developments guided by unique Robust Design metrics and processes.

Smarter product performance

Updated product architecture and system design to yield performance of primary functions

Are you interested in hearing more

quality management and robust engineering processes?

Book a meeting with us already today