Mechanical Engineering

What is engineering design?

There exist many disciplines of engineering design - ranging from biology to mechanics to software. At RD8 we focus on engineering design and applied mechanics (mechanical engineering) - hereby the art of putting a lot of engineering disciplines within mechanical engineering together. There exist a lot of very specific know-how within fields such as fluid dynamics, material science, concept development - but very little know-how about how science and different disciplines materialize into physical parts, interfaces, and products. Robust Design embraces the art of materializing different disciplines into geometry that forms robust products and systems.

Engineering Efficiency

Engineering design: how to stay efficient

Data driven product development and low complexity are key for time-to-quality.

RD8’s Robust Design methods are a framework and insurance towards the ideal product quality along the development path. Our methods provide the ability to check and validate the robustness of a product design from the early design stages and along the development path – maximizing the ability to deliver high quality right the first time at the right cost.

A typical product development path is illustrated below.

Step 1: INDEX 100 is defined as the projected development cost.

Step 2: The “design freedom” or “ease of change” is plotted onto the second axis of the graph. The later the change occurs the more expensive it is to correct or implement a solution.

Step 3: The typical project cost. Typically at the end of the design phase or after design release (after detailed design), the cost exceeds the projected budget. Unexpected issues occur. As mentioned in “Step 2” these changes are often costly and cause the project costs to drift. Late project changes can lead to +INDEX 150 cost impact.

Step 4: The RD8 RES way – enables transparency along the design process and ensures healthy technical solutions the first time. Result: lower risk of budget drifts & possibly cost/time/resource reductions.

Issues in engineering design

Mapping & logging of change notes

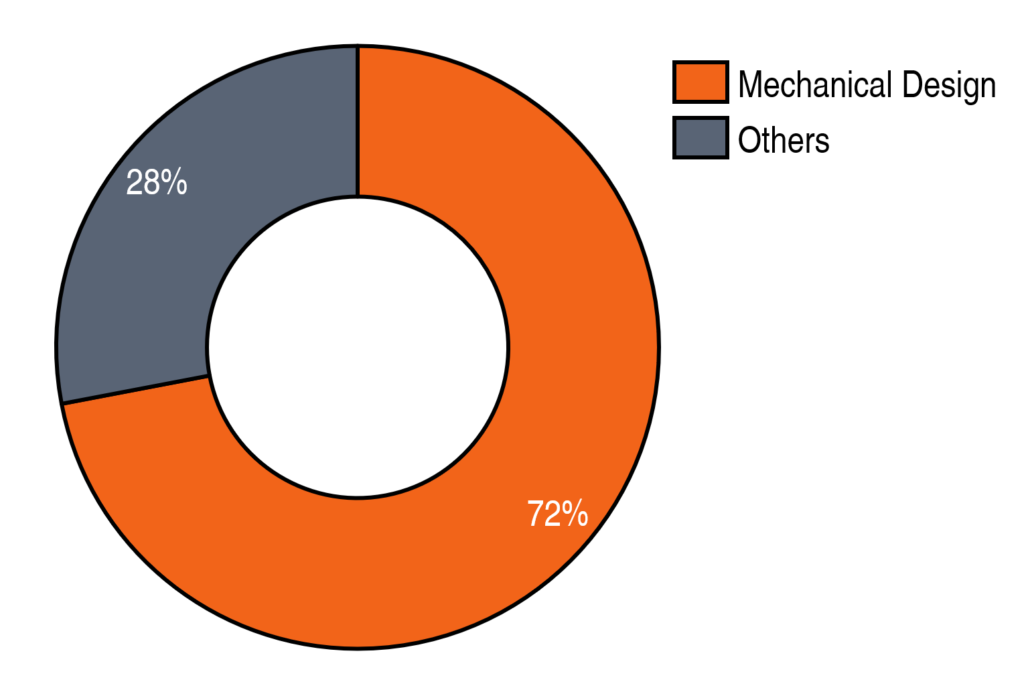

What is the root cause for detours in engineering design and new product launches? Mechanical design account for 72% of issues according to academic studies.

Academic studies prove what causes development projects to go “off-track”.

Studies by Martin Ebro, Jesper Olesen, Thomas J. Howard shows that app. 72% of change notes (based on tracking of 4 projects) were related to mechanical issues – in the groups:

- Design clarity

- Tolerances

- DFA

- Structural

The aim of Robust Design methods – is to prevent these issues so they do not turn into expensive late project changes.

Source: “Robust Design Impact Metrics: Measuring the effect of implementing and using Robust Design”; Ebro, Martin; Olesen, Jesper; Howard, Thomas J.; Published in: Proceedings of the First International Symposium of Robust Design 2014

Robust Design

8 principles of engineering design

Working smarter and more data driven in R&D by guiding metrics

Design metrics for

To prevent detours and unexpected failures objective design metrics are the key. The RD8 robust engineering system is based on 8 Robust Design disciplines – each represented by a unique objective metric that can be scored across all product types and industries and be normalized to be compared across products.

The metrics are used actively during the product development process and bring objective values to evaluate the maturity and quality of a design. This ensures healthy design first time and often prevents detours (extra project loops, change orders, costly test programs, etc.) – and hereby project cost.

Insight into each discipline adds transparency and supports the decision-making and project focus to reduce risk and communicate to stakeholders and the development team.

More than a 25% reduction of timeline by next-level integrated product development is the goal for our Robust Design way of working.