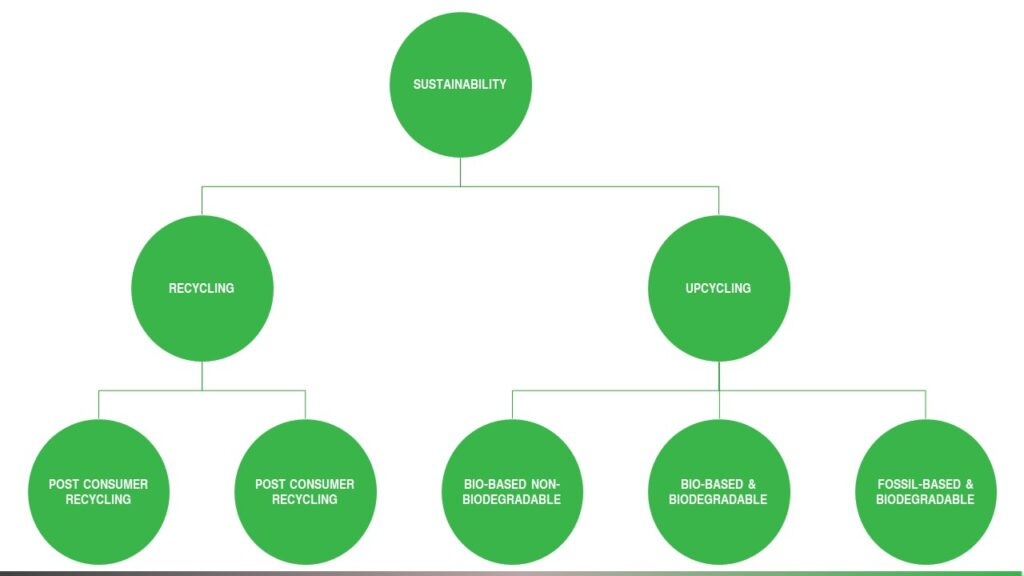

Upcycling vs. recycling

To understand the difference between upcycling and recycling some terms are defined below. In essence, the difference between upcycling and recycling is that in upcycling, additional, new (virgin) material or additives are mixed into the recycled material to enhance the appearance or mechanical properties. Hence an upcycled material is a recycled material with something added to it - where that "something" is not recycled content.

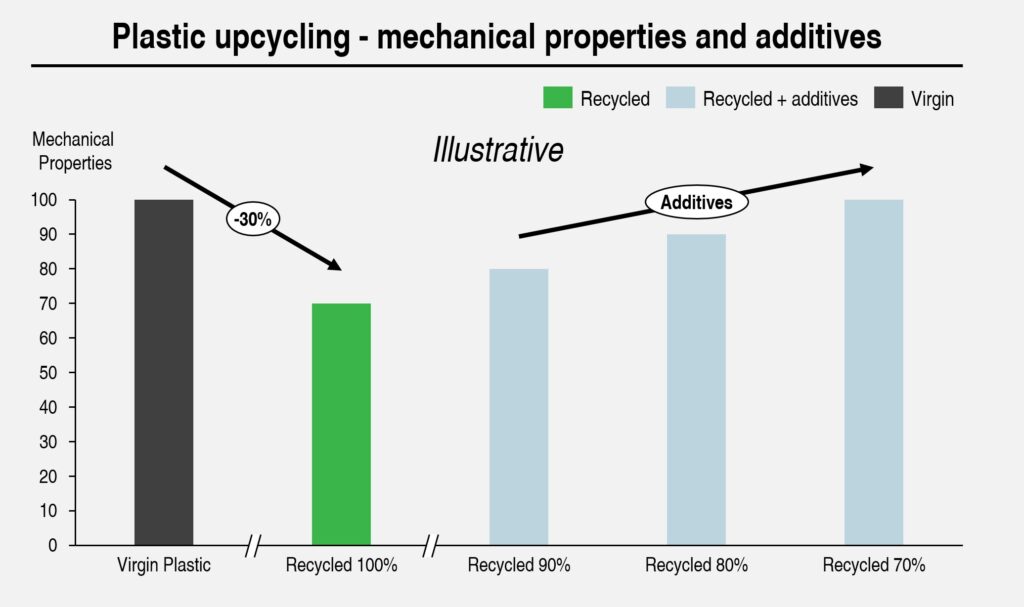

Plastic upcycling

The mechanical properties of recycled plastics are lower than commercial virgin materials since recycled plastics are a mix of different materials due to sorting and cleaning processes. To compensate for this, and be able to use the recycled plastics as technical plastics, additives such as UV-stabilizers, flammability-stabilizers, glass fibres, etc., are added to get the desired mechanical properties – thus, the amount of recycle-percentage decreases.

Challenge

By adding additives the density increases yet the plastic will not float. This makes the plastic harder to recycle in recycling facilities. This also means that if it ends at sea, it will sink and end at the bottom. Which can be a disqualifier for sustainable material selection.

Colors

For recycled materials - it is hard to control the color of the incoming material - hence it is hard to reach 100% recycling if requirements for color are stated in the product requirements. To reach 100% often product requirements have to be challenged. Typically the color of the final blend is black - BLACK IS THE NEW GREEN. Thus, a few suppliers can deliver in some colors. It can be done.

Smell

There can be a scent of the recycled materials depending on the recycling source.

Plastic recycling

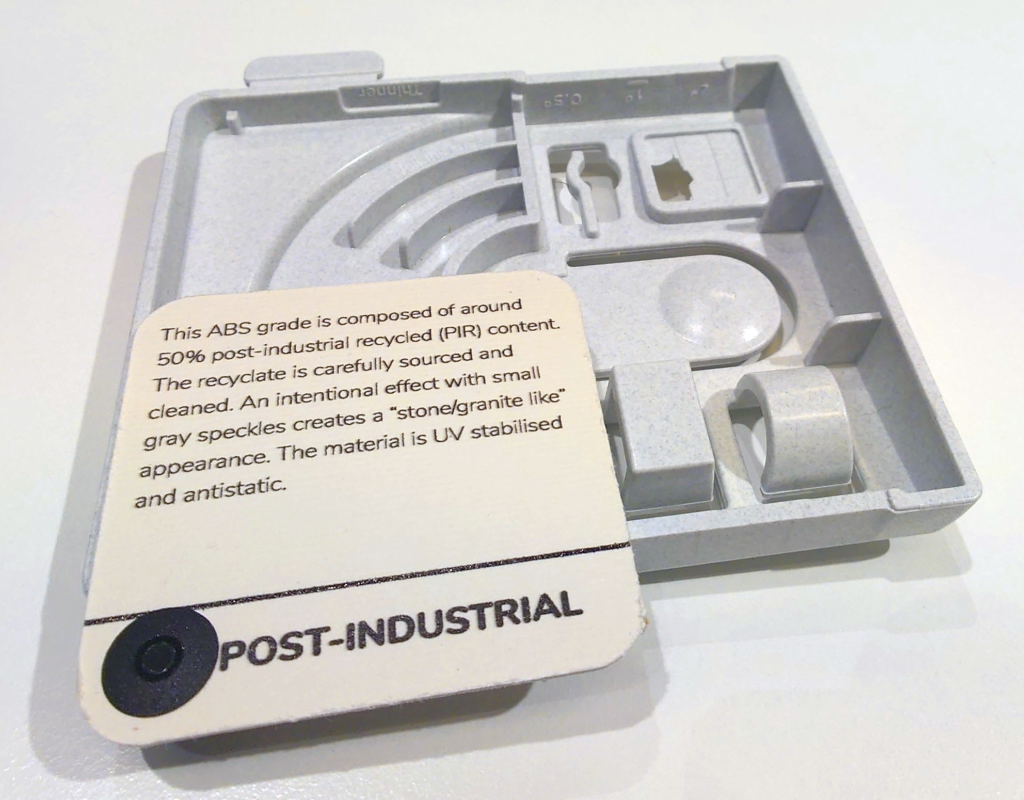

Post Industrial Recycling

Plastic (waste) that is reused from production – e.g. plastic from the production scrap bin. It is plastic that has not been out to the consumers.

Example of post-industrial material sample with 50% recycled content

Post consumer recycling

Plastic that is reused after it has been at the consumer – typically collected from return systems. It is cleaned and/or sorted by specialized industrial companies. The CO2 footprint from this source is typically higher than post-industrial recycling as the supply chain is longer (more transport) and cleaning/sorting steps are included (which typically includes hot water which is energy heavy).

Example of post-consumer material sample with minimum 50% recycled content. 20% talc filler added + UV-stabilized

Bio-based plastics

Bio-based non-biodegradable

Bio-based plastics are plastics that are made from renewable biological resources e.g. sugar cane, corn, or other leftovers from agriculture. Non-biodegradable means that the plastic will not automatically degrade in nature. This is good if you want to recycle the material – it is bad if you leave it the nature. The energy consumption to make the bio-based material can be higher than fossil-based production.

Example of bio-based material sample with 45% bio-based content

Bio-based & biodegradable

Based on renewable processes and can be degraded in nature. it is difficult to reuse these types of plastics as they degrade with time. These types of plastics are often seen as pollution in recycling processes as their mechanical properties change over time and influence the need for constant material quality.

Fossil-based & biodegradable

Fossil-based and biodegradable production represent plastics that are produced by fossil-based production methods but are biodegradable – meaning that the plastics in a given environment will be degraded by microorganisms.

See more about bio-based plastic definitions here.

Recycling vs. biodegradeble

The difference between recycled and biodegradable materials is that biodegradable materials are hard to recycle as they are designed to degrade very fast in a given environment.

The paper (biodegrade) straw vs. the plastic (recyclable) straw

The biodegradable straw

The biodegradable straw – in this example, a paper straw can be left in nature, and it will degrade over time.

Because the straw degrades very fast, it cannot be used for recycling purposes thus the material is “lost”. The energy that was used for the creation of the straw is lost.

The recycled straw

The recycled straw – in this example, a plastic straw cannot be left in nature because it will not degrade over time (compared to the lifespan of a person). If left in nature it will take many years to degrade and there is a risk that the plastic straw will end up in the belly of a turtle or a fish.

In another scenario, the straw ends in a recycling eco-system where it can be used for recycling purposes. Hence the material is not lost and the energy and CO2 emissions that went into creating the material can be reused to minimize the CO2 footprint of the second use of the material.

Aluminum: recycling facts

Primary vs. recycled aluminum

Typically there is no difference in mechanical properties or expected tolerances in primary (“virgin”) vs. recycled aluminum.

Thus some alloys cannot be made “the recycled way” from “post-consumer recycling“. “Post-industrial recycling” is easier as the alloy composition is known and can be reused.

If appearance is important – note that despite that the mechanical properties are the same – anodizing can vary from product-product when using recycled alternatives.

Alloy types

Recycled alternatives are a mix of scrap/recycling types which in most cases are difficult to separate and extract into exact alloy compositions/chemical compositions.

This typically limits the production of the cleanest types of alloys with extremely low content of Fe, Cr, Zn, Cu, and various trace elements.

Price

Making recycled aluminum requires only a fraction of the energy of making a primary ingot thus recycled aluminum is typically slightly more expensive than primary ingot due to the cost of the separation and recycling system.

Links

Check out more at:

- Hydro.com – link to Hydro’s recycled materials

- Alumeco.com – link to Alumencos recycled materials. Note that they offer both recycled options and primary ingot made by green/renewable energy sources.