What is greenwashing?

Greenwashing is a global issue. It is a saying for the mismatch between what companies say they do to lower their climate footprint and what they do. If statement and action do not match then this is called greenwashing. As such, greenwashing is the act of misleading consumers into thinking a product or company is “green” or “eco-friendly – more than they actually are. It can be double counting CO2 emission reductions or branding a product as totally green and it may only be partly green. As such, the act of greenwashing makes it hard for the average consumer to see through the mirage of deceptive claims and thus making it difficult to make genuinely eco-friendly choices.

Below are some facts to highlight and explain some of the perspectives behind and to better navigate the green aspects.

Picture of the OBEL AWARD artifact in Copenhagen, Denmark, July 2023.

Fact 1

An example of greenwashing in Denmark

...a little too smart

An example of greenwashing or where it is very hard for the public to judge what is true – is a story from the Danish municipalities.

The commune of Copenhagen owns Hofor (a danish energy company) which owns 22 windmills located on Lolland (app. 150 km from Copenhagen).

The issue is that both the commune of Copenhagen and the commune of Lolland (where the windmills are located) include the CO2 reductions from the windmills in the CO2 accounting – hence double counting.

The CO2 reduction can of course only be counted once. It harvests the energy in one place – not in both places.

Read more about the story in detail here:

Fact 2

How greenwashing makes products attractive

The first real green steps are hard

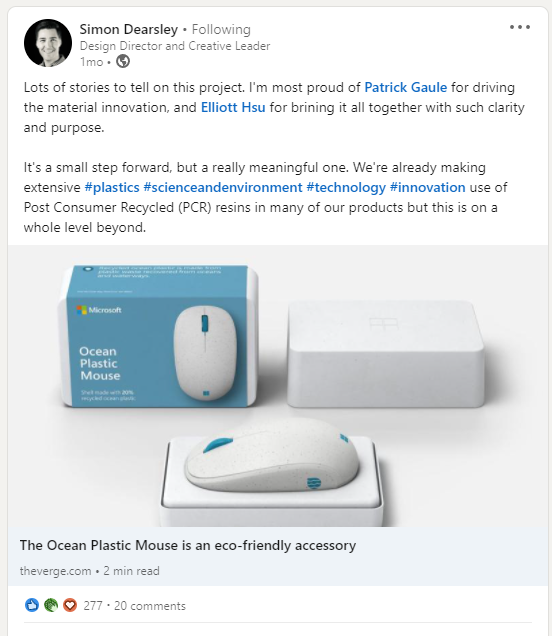

Companies are proud to show their efforts and want to get the most out of them. It is not easy to go 100% green for technical products in the first take. This is sometimes interpreted as greenwashing as headlines can be a bit misleading.

In this case, Microsoft launches and promotes a new “Ocean Plastic Mouse” which is “a whole level beyond” – and they explain how much effort they have put into this first iteration of green design. But as you see in the comment below from LinkedIn – not all customers/potential customers are satisfied when they read the details in the fine print. The mouse shell is “made of 20 percent recycled ocean plastic and the packaging is 100 percent recyclable”. Consumers probably expect a higher degree of recycling based on the name of the product.

Fact 3

Greenwashing and the greenhouse gas protocol framework

The greenhouse gas protocol framework

A lot of companies are reviewing their sustainability efforts and working with baselining their current or past emissions. The framework that is widely used to account for CO2 emissions is the Greenhouse Gas Protocol (GHGP) – see more at https://ghgprotocol.org.

The greenhouse gas protocol dictates 3 scopes into which different types of emissions are divided – read more about them here.

Scope 3 = complex

Scope 1 and 2 are less extensive than scope 3 and sometimes not all of scope 3 emissions are included in sustainability reports as these parts have not been covered yet – thus these can be a huge part of the company’s carbon footprint. Many of scope 3’s contributions require extensive qualification and lifecycle analysis for the products – which can be complex – and in some cases, it is out of the manufacturing companies’ reach.

For example, Scope 3 includes “end of life” and “use of sold product” aspects which in some reports are not yet included, and thus the given sustainability report may only tell half the story or not all of the story.

Science-Based Targets

To add transparency many ambitious companies commit to the “science-based targets” framework and commit to CO2 emissions to comply with the 2015 Paris agreement.

The site offers a nice feature where you can look up companies and their committed efforts.

Fact 4

Where are the emissions - where to get bang for the buck

The greenhouse gas protocol scopes and CO2 emissions efforts

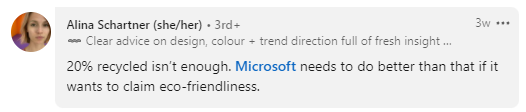

For product manufacturing companies; in most cases, scope 3 is by far the biggest source of greenhouse gas emissions. We have picked 12 product manufacturing companies from different industries and compared the shares of greenhouse gas emissions. Scope 2 and 3 account for more than 95% on average.

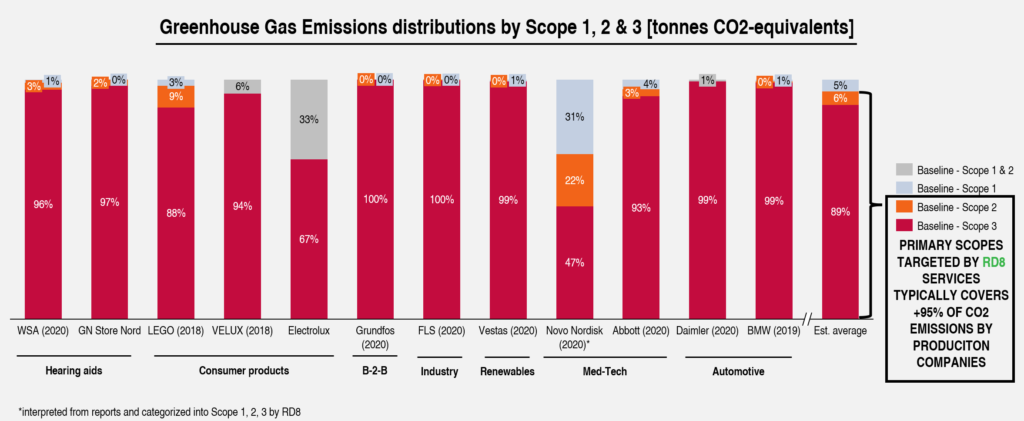

In many cases, the low-hanging fruits are to reduce scope 1 (company facilities CO2 emissions and company vehicles CO2 emissions) and scope 2 (purchased electricity, steam, heating & cooling for own use related CO2 emissions) which account for very few percentages and is often solved by purchasing of energy from renewable sources, optimization of company facilities and use of CO2 friendly vehicles.

This can for many companies create nice headlines which are true but do not solve the primary source of CO2 emissions that are originating from scope 3; the use and manufacturing of the actual product that the company makes.

In the example to the left, the company is switching to 100% renewable energy sources, which are great, but it only covers 3% of the company’s CO2 emissions.

Fact 5

Why do companies greenwash their products?

Why does greenwashing exist? Hopefully, because companies want to perform better than they are – and have a hard time catching up with the promises.

On the other hand, it is very difficult to reduce many of the scope 3 emissions due to various challenges.

3 examples:

- Sourcing: work with new suppliers, ensure availability and supply of materials

- Working with green materials can create technical challenges:

- inconsistent behavior of materials

- batch to batch variation of materials

- materials with weaker mechanical properties

- issues with certifications and regulations

- Eco-systems for recycling or end-of-life upcycling have to be set up

To the left is an example of circularity challenges.

A perspective on how to ease the effort for CO2 emissions reductions:

- Reduce product complexity to state fewer requirements for part manufacturing and assembly.

- Reduce component requirements to enable the use of green materials

- Set up guidelines for “design for sustainability” in product development. Ensure easy and non-destructive disassembly of products to separate or upcycle parts/modules.

Robust Design is an engineering tool that supports these activities.

Fact 6

Example of a CO2 reduction lever

Aluminum is a commodity and can be purchased in primary (virgin) and secondary (recycled) ingot.

The mechanical properties are almost the same.

The cost is almost the same.

The CO2 footprint is very different! Depending on supply chain details – the estimated difference in CO2 footprint is around 90 percent. Read more here.

Get inspiration for more CO2 reduction levers by design

Fact 7

Design for 100% recycling of plastic components

At 100% recycling of plastics the end blend is depending on the incoming, recycled, content. This results in that there will be a variation from batch to batch of mechanical properties, e.g.:

- Stiffness

- Yield strength

- Tensile strength

- MFI (Melt Flow Index)

The mechanical engineer would face challenges in the design – as the designer would need to design for the lowest expected boundary.

The injection moulder would experience that the machine cannot run with the same settings from batch-to-batch.