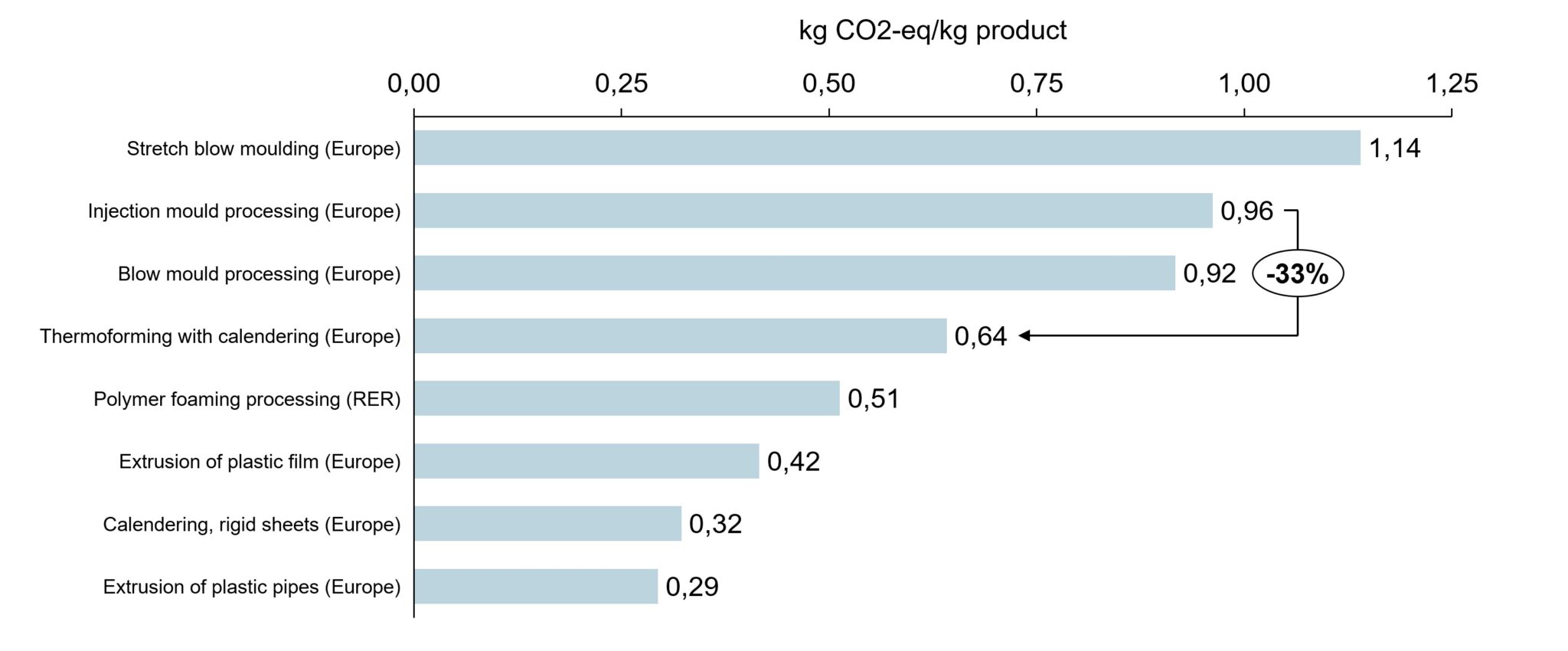

CO2 emissions & production processes

Changing part production from one production process to another can reduce CO2 emissions. It is illustrated that a 33% reduction can be achieved by changing from injection molding to thermoforming.

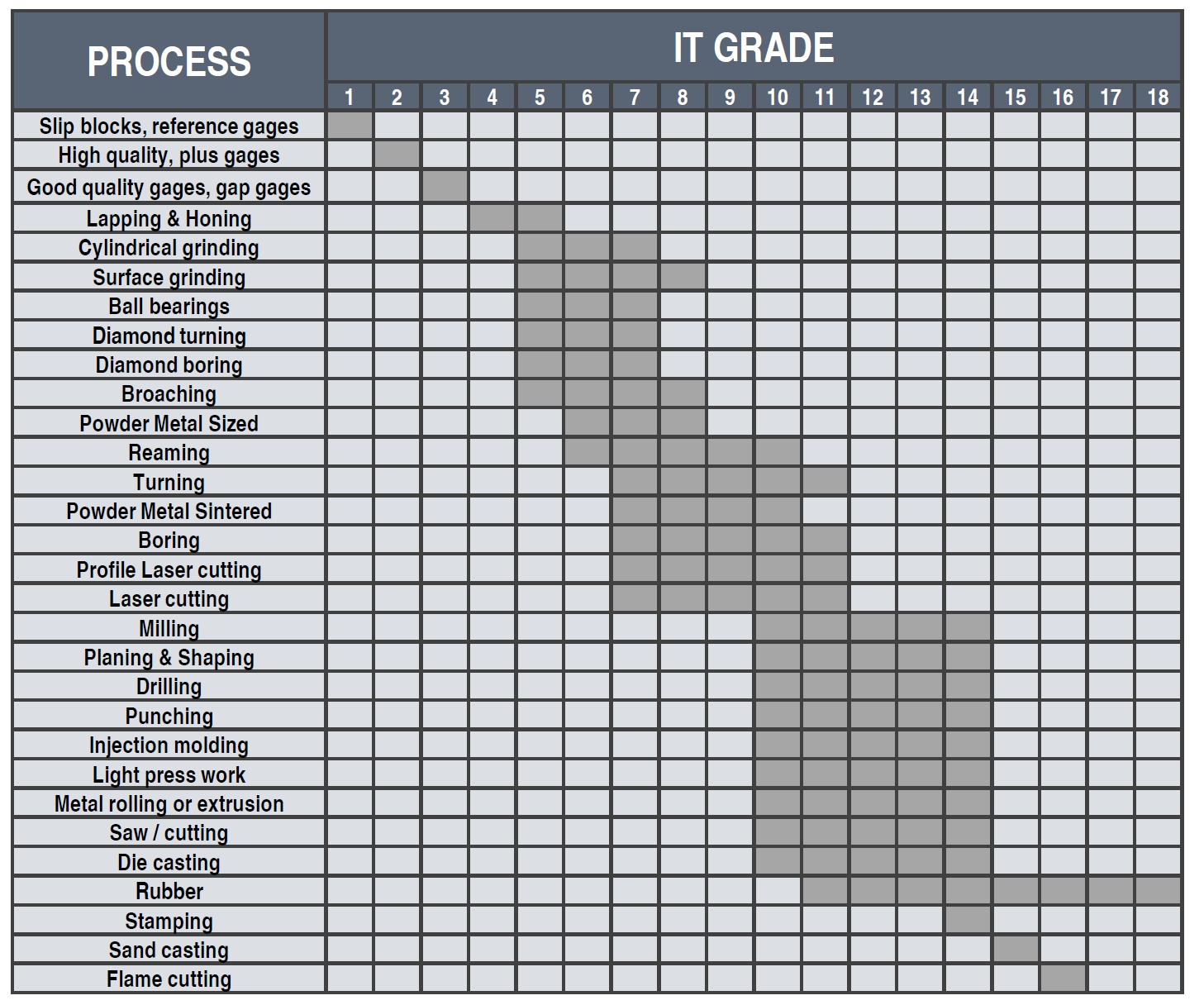

Changing from one process to another often requires a lot of important considerations – one of them: tolerances. Production processes have different production capabilities. The chart below shows international tolerance grade ranges for different production processes. A higher grade equals wider and more course tolerances.

In the example going from reaming (IT6 to IT10) to drilling (IT10 to IT14) will result in expected wider tolerances.

The Robust Design of components can enable the use of more course production processes which are often cheaper and more energy/CO2 efficient.

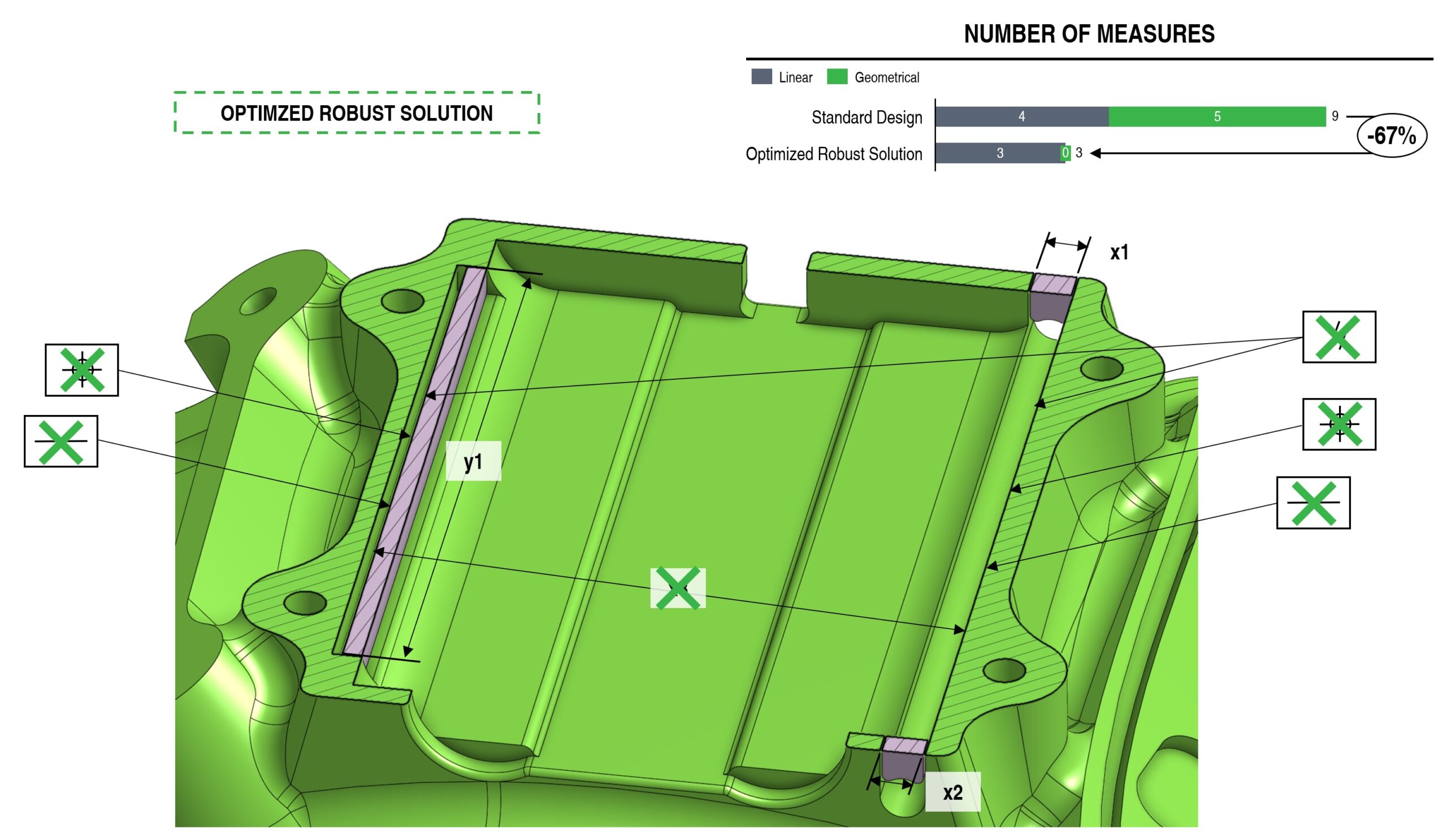

The illustration shows two designs – a standard design and an optimized robust solution. Linear and geometrical tolerances are indicated in the illustration (in practice the measures should be shown on both parts through the percent-wise evaluation will be the same).

Standard design

- Three measures in the x-direction

- One measure in the y-direction

- Requirements to parallelism for the two ribs and their counterfits

- Position requirements ribs placement relative to “x1” and “x2” features

- Straightness requirements to ribs and counterparts

Optimized Robust Solution

- Two measures in the x-direction

- One measure in the y-direction

Requirements to parallelism for the two ribs and their counterfitsPosition requirements ribs placement relative to “x1” and “x2” featuresStraightness requirements to ribs and counterparts

A reduction of measurements is one of the keys to wider tolerances and production process changes. In the given example a reduction of linear measures is decreased by 67%. Enabling a more course production process, hence making the production cheaper and more energy and CO2 efficient.

Are you interested in hearing more about CO2

reductions by production process change?

Book a meeting with us already today