Robust Design & CO2 protocol

Robust Design is a means to reduce CO2 emissions. The section below will bring perspectives on how to reduce CO2 emissions by Robust Design. The RD8 services targets scope 2 and 3 (none of the services affect scope 1).

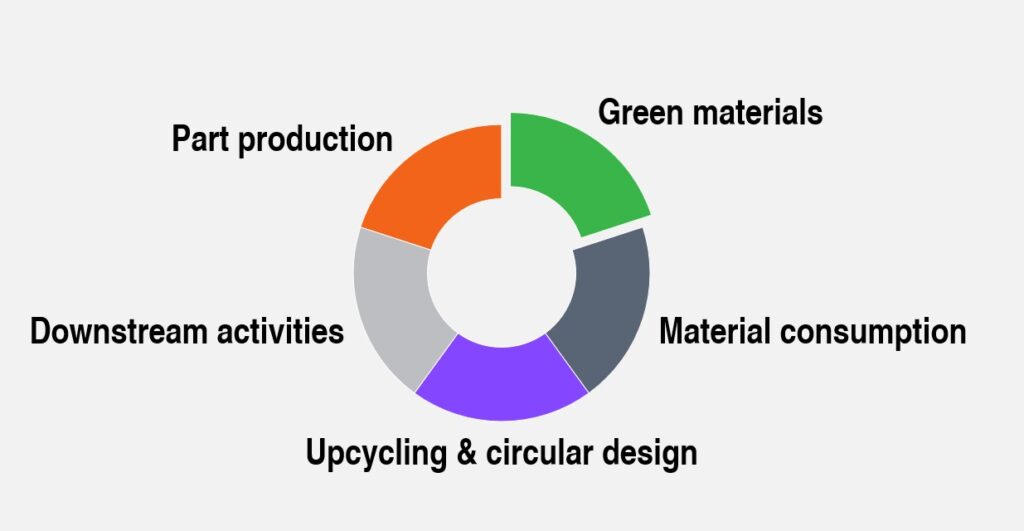

RD8 sustainability levers – 5 levers to reduce CO2 emissions by design.

Details of each lever are described in the table below and the sections further down on this page.

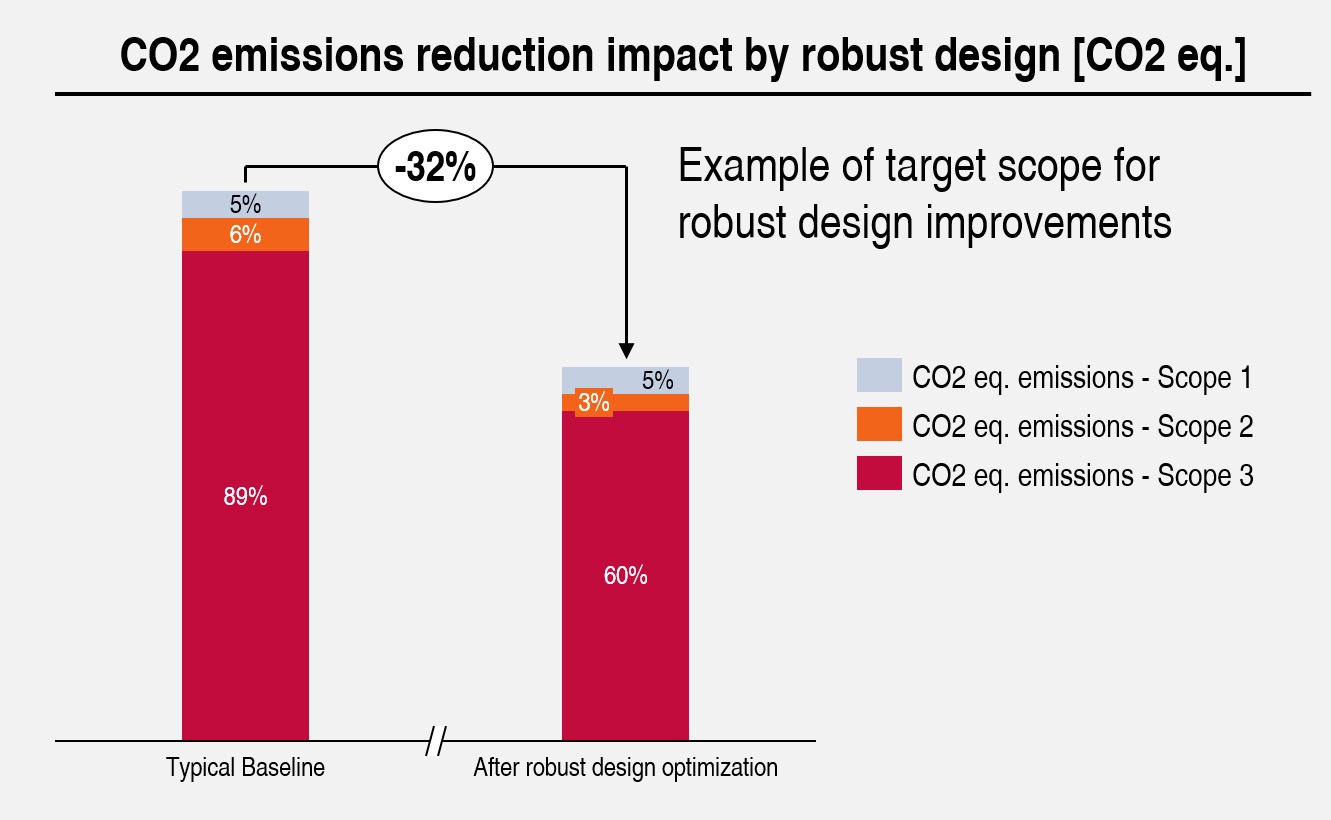

The intended effect of the RD8 Robust Design levers is shown in the graph below.

The intend is to lower primarily scope 2 and scope 3 emissions by Robust Design product and production system optimizations. For more info about the baseline have a look here.

The effect of CO2 reductions are product dependent. See examples of the drivers for CO2 effects in the sections below and in the sub-articles for more in-depth information.

The table below shows Robust Design services for engineering professionals to lower CO2 emissions by design.

| RD8 ENABLING SERVICE | GHG PROTOCOL SCOPE | SCIENCE BASED TARGET EXAMPLES | ||

|---|---|---|---|---|

| PRODUCTION PROCESS CHANGE | SCOPE 2 | CO2 reductions by change to less CO2 consuming part-manufacturing processes | 5%-20% | |

| PRODUCTION EFFICIENCY | SCOPE 2 | CO2 reductions by producing more with the same. Lowers CO2 emissions per product made. | 10%-30% | |

| CO2 REDUCTIONS BY MATERIAL REPLACEMENT | SCOPE 3 | CO2 reductions by material replacement. See more here. | 5%-90% | |

| OPTIMIZATION OF OVER ENGINEERED DESIGNS | SCOPE 3 | CO2 reductions by material optimization (less kg material used per product). | 5%-20% | |

| SCRAP REDUCTION | SCOPE 3 | CO2 reductions by preventing material waste in production. | 50%-75% | |

| DIS- & RE-ASSEMBLY | SCOPE 3 | CO2 reductions by increased product lifetime by enablement of product disassembly and reassembly. | 25%-75% | |

| SPARE PARTS & SERVICE ENABLEMENT | SCOPE 3 | CO2 reductions by increased lifetime. CO2 emissions per year is lowered as product lifetime is increased. | 25%-75% | |

| INCREASE PRODUCT LIFETIME | SCOPE 3 | CO2 reductions by increased lifetime. CO2 emissions per year is lowered as product lifetime is increased. | 25%-75% | |

| ENERGY OPTIMIZATION | SCOPE 3 | CO2 reductions by increased product efficiency. | 1%-10% | |

The greenhouse gas protocol

Setting the scene.

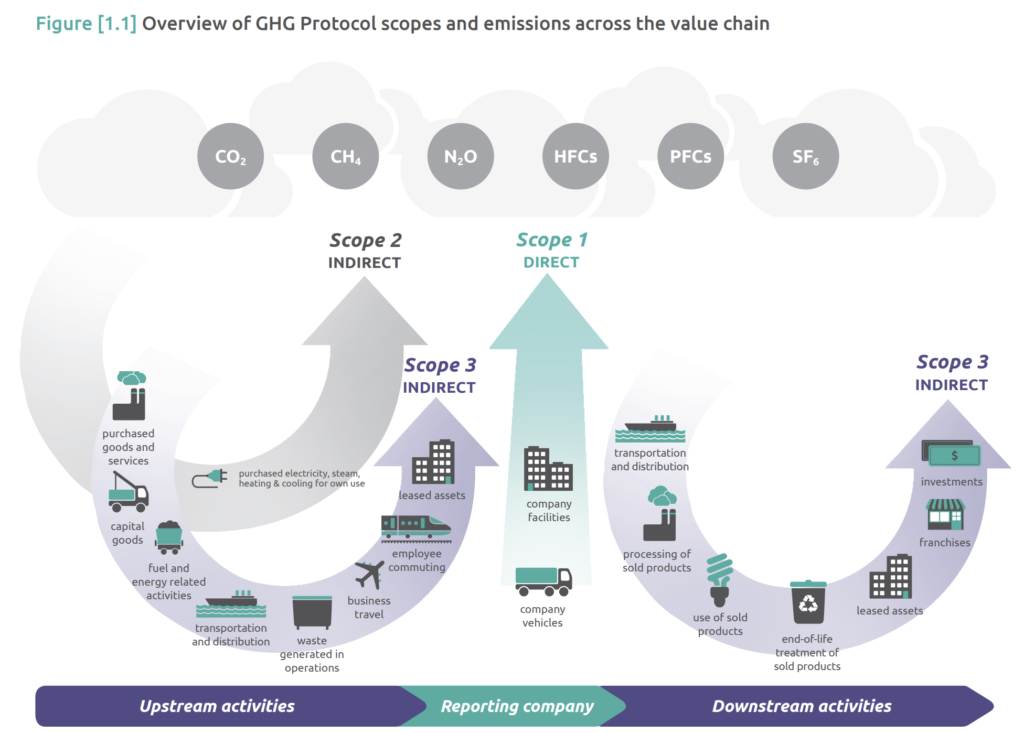

The standards within the GHG Protocol are the world’s most widely used greenhouse gas accounting standards. It provides a framework for businesses, governments, and other entities to measure and report their greenhouse gas emissions in ways that support their missions and goals.

A short video introduction to the greenhouse gas protocol – a “global standardized framework to measure and manage Greenhouse Gas (GHG) emissions from private and public sector operations, value chains, and mitigation actions.“

Scope 1, 2 & 3

From an operations point of view, CO2 emissions are classified by “scope 1, 2, and 3” – defined by greenhouse gas protocol and often referred to – e.g., by EPA (the United States Environmental Protection Agency) – illustrated below by GHGP.

RD8 supports “reporting companies” to lower emissions in primarily scope 2 and scope 3.

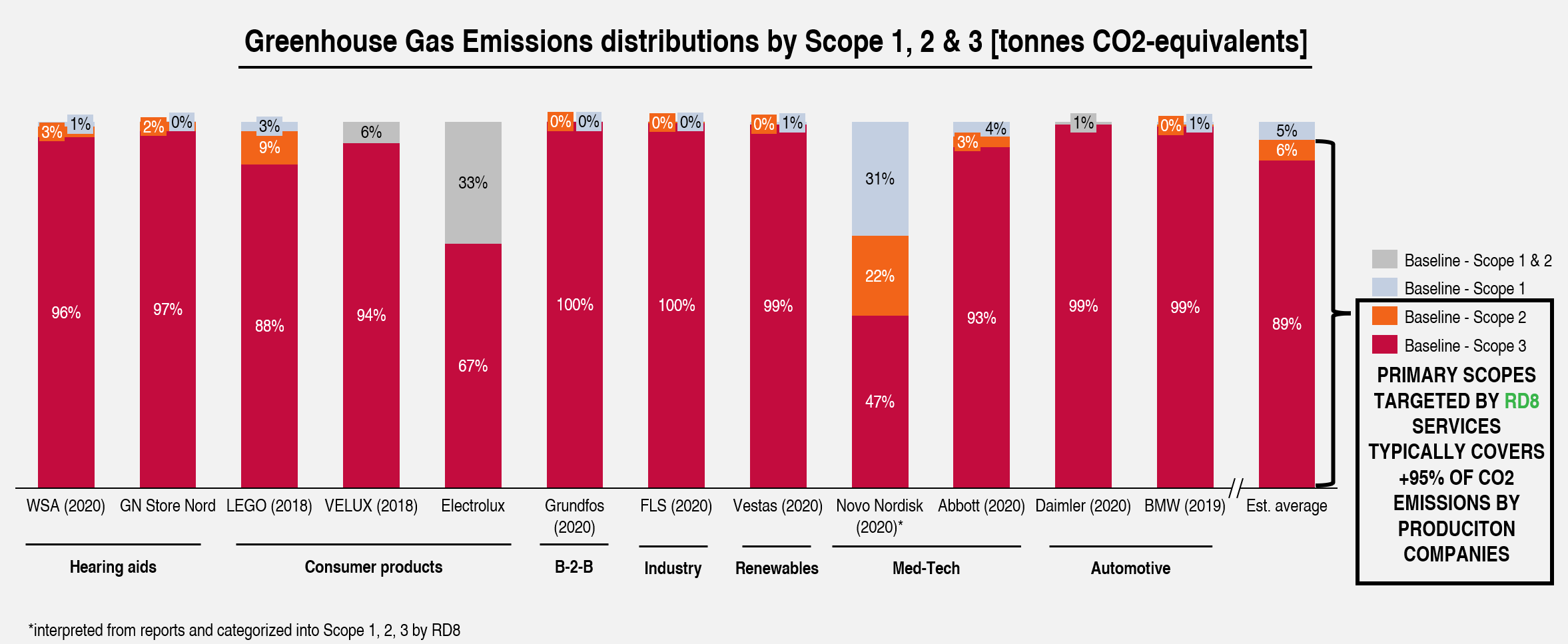

CO2 emissions from production companies is primary from scope 2 and 3 sources

The primary scopes which typically covers +90% of production companies CO2 emissions are targeted by RD8 services.

A brief look across product development and production companies shows that the primary drivers for CO2 emissions are scopes 2 and 3. This is based upon looking at the baselines in companies’ latest sustainability/ESG reports. In some reports it was not possible to distinguish between scope 1 and 2 emissions – in these cases, data have been pooled together.

Scope 3 is by far the primary source to target CO2 reductions. Read more about the scopes and how RD8 services affect the different scopes. The Novo Nordisk case is the one sample with the lowest scope 2 and scope 3 coverage. Novo Nordisk differentiates from the rest of the cases – probably due to that Novo Nordisk does not only sell mechanical devices but also drugs.

A lot of the low-hanging fruits like reusing exhaust energy in production, installing solar panels, sorting garbage, reducing paper usage, reduction of one-time cutlery, etc., which are not the core of a company’s business have been implemented.

RD8 services target the actual product – the core – and the actual primary source of CO2 emissions. Concerning the greenhouse gas emissions protocol, RD8 services target scopes 2 and 3, and especially scope 3.

We work with partners specializing in ESG/CSR to support ESG/CSR strategy, reporting, baselining, and much more.

Scope 2: how Robust Design plays a central role in lowering energy consumption in production by mechanical design

Lowering of CO2 emissions from purchased electricity, steam, heating & cooling.

Scope 2 - production process change

Reduction of tolerance requirements can enable low energy production processes. Being aware of production processes' energy and CO2 emissions can be a source to lower CO2 emissions.

Scope 2 - production efficiency

Reduction of tolerance requirements enables more energy efficient operations. Lowering of production demands reduces energy used per product. If 4 parts can be made instead of one in a production cycle - e.g., injection molding, stamping, or similar the energy per unit is typically lowered. The same goes for if cycle time can be lowered meaning the machine output is increased. The trick to achieving this is to lower the requirement for tolerances. Increasing the speed or number of products per cycle typically results in less accurate parts. By applying Robust Design principles the requirements to accuracy and tolerance demands are lowered for the product and hence lower energy consumption can be achieved.

Scope 3: reduction of scope 3 CO2 emissions by Robust Design

Lowering of CO2 emissions from processing energy, scrap & use of sold products.

Scope 3: CO2 reductions by material replacement

Eased tolerances enable the use of new green materials. The technical effect of a Robust Design application is typically eased- and fewer tolerances - which can be utilized to enable production with green or recycled materials which have less good mechanical properties.

Scope 3: optimization of over engineered designs

Less material use by reduction of over engineering. In over complex designs force paths are not clear - and internal stresses are present due to part- and assembly variation. To compensate for this the solution is often to add extra material to the product design. By applying Robust Design the force paths will be clear and reduction of internal stresses in components can be achieved, which opens a window for optimization - if utilized - this results in less material use.

Scope 3: scrap reduction

Eased tolerances, consistent quality, and increased predictability of product functions result in less material scrap on the shop floor. One of the major gains of robust design is repeatability and fewer demands on parts and assembly. The benefit of this is that fewer materials and parts will be scrapped in the QA process and hence less material waste can be gained.

Scope 3: dis- & re-assembly

Stress free designs enable reuse and increased lifetime of products. In over constraint interfaces and assemblies, internal stresses arise due to part-to-part variation in some samples. Internal stresses often lead to deformed parts or that parts will break/deform during disassembly - this limits the possibility of reuse. By Robust Design internal stresses can be avoided and hence disassembly without deformation/break of parts can be obtained. This enables the reuse of products and hereby increases the lifetime and lowers the CO2 emissions per year as product lifetime is increased.

Scope 3: spare parts & service enablement

Modular Robust Design enables the replacement of modules and spare parts. Ensuring serviceability and use of spare parts can increase product lifetime and hereby CO2 reductions per year as product lifetime can be increased. In some designs, spare parts are so delicate that spare parts cannot be used as a need for a mix 'n' match. In other cases worn or exposed parts cannot be replaced as they are a part of the key structure of the product - for example, the screen of some smartphones is expensive to replace if it is broken due to how the rest of the smartphone construction is coupled (linked) to this part. By decoupled design, these links and dependencies can often be broken to enable serviceability.

Scope 3: increase product lifetime

Stress free designs = increased product lifetime. Over constraint, design induces internal stresses in products. Internal stresses in moving mechanics are often the root cause to lower product life as parts with higher stresses are exposed to faster wear and tear. By Robust Design, internal stresses in products can be eliminated or lowered to achieve a longer lifespan of parts and products. This results in a longer product lifetime and thereby lower CO2 emissions per year for the products.

Scope 3: energy optimization

Lower energy consumption in sold products can be achieved by kinematic design. Kinematic design is the foundation for RD8's Robust Design principles. One of the major benefits of a correct kinematic design is less internal stresses in moving parts and hence less friction in the system. The yield of this is that less energy has to be used to drive a product with moving parts - and hereby energy and CO2 consumption in sold products can be reduced.

Are you interested in hearing more about Robust

Design & the Greenhouse Gas Protocol (GHG)?

Book a meeting with us already today