Robust Design definition

The term “robust” is often misinterpreted as a tough, somewhat strong, rigid, and well dimensioned design, but that is not the case. The term is better described by its opposite: “sensitive”. Thus, a Robust Design is not sensitive – meaning that variation in the product will have minimal influence.

In essence, the meaning of Robust Design is to minimize the impact of variation in a product. For example, suppose the product gets exposed to variation in production (e.g., tolerances or material abnormalities) or use case (e.g., where the user is applying force or holding the product). In that case, the end-user should not experience any change in the product’s behavior.

To put it into simple terms. For example, you would characterize an old Toyota Hilux as a robust product as it will work day & night, even though exposed to dust, mud, wear & tear – even demolition. See how Top Gear tries to “kill a Toyota” with no success. (Part 1, Part 2, Part 3).

On the other hand, some Danish trains (e.g. IC4) are characterized as sensitive as they may not work when it is cold, it is snow or there are leaves on the track.

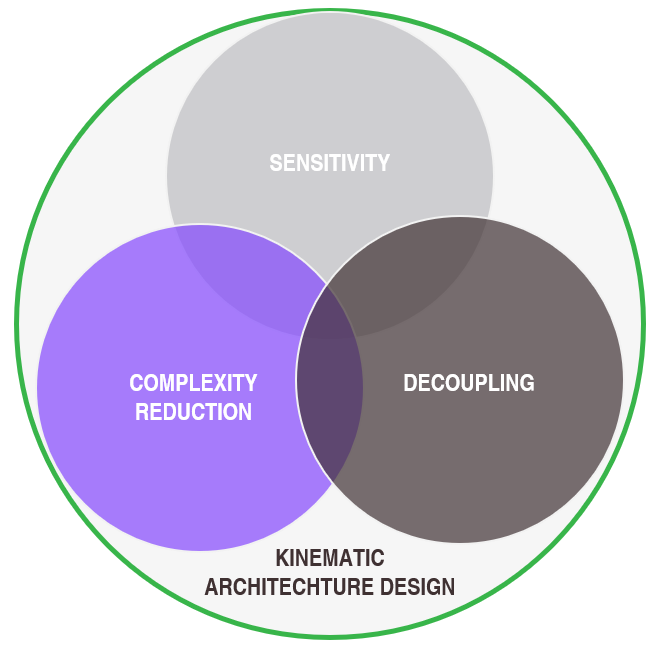

Classically Robust Design is based on theories with areas and names:

Taguchi methods (sub-set to Six Sigma) – Genichi Taguchi

- The topic here is “sensitivity”

Axiomatic design – Nam Pyo Suh

- Topics here are “complexity reduction” & “decoupling”

At RD8, we combine classic Robust Design methods with the theory of moving mechanics. Notions here are “mobility” and “kinematic design.”

We claim that Taguchi methods and axiomatic design are hard to master if the kinematic foundation is not set.

You will need dedicated experts and experience to use the methods. And often, you will not gain the benefits in everyday development situations as the methods are hard to use if the foundation is not paved-ready.

The RD8 solutions offer the power of traditional Robust Design disciplines, combined with the latest industry experience with a more holistic and wide-coverage view – topped off with the newest technology and research to serve our expertise in a simple and user-friendly interface – for engineering professionals to yield the most.

RD8 Robust Design principles

Objective design metrics

Data driven product development. The RD8 Robust Design methods quantify and scores conditions of designs to provide transparent and data driven solutions.

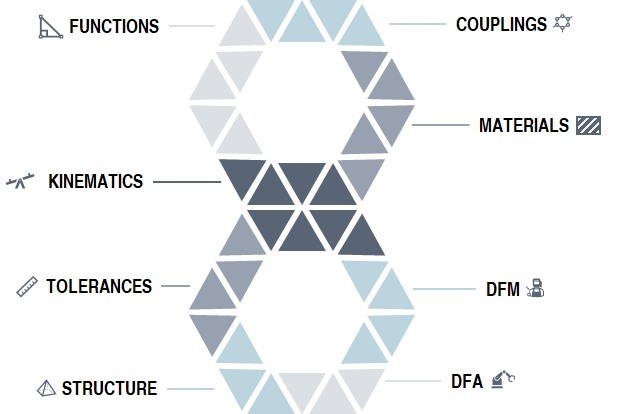

Scoring a product design by 8 robust design metrics

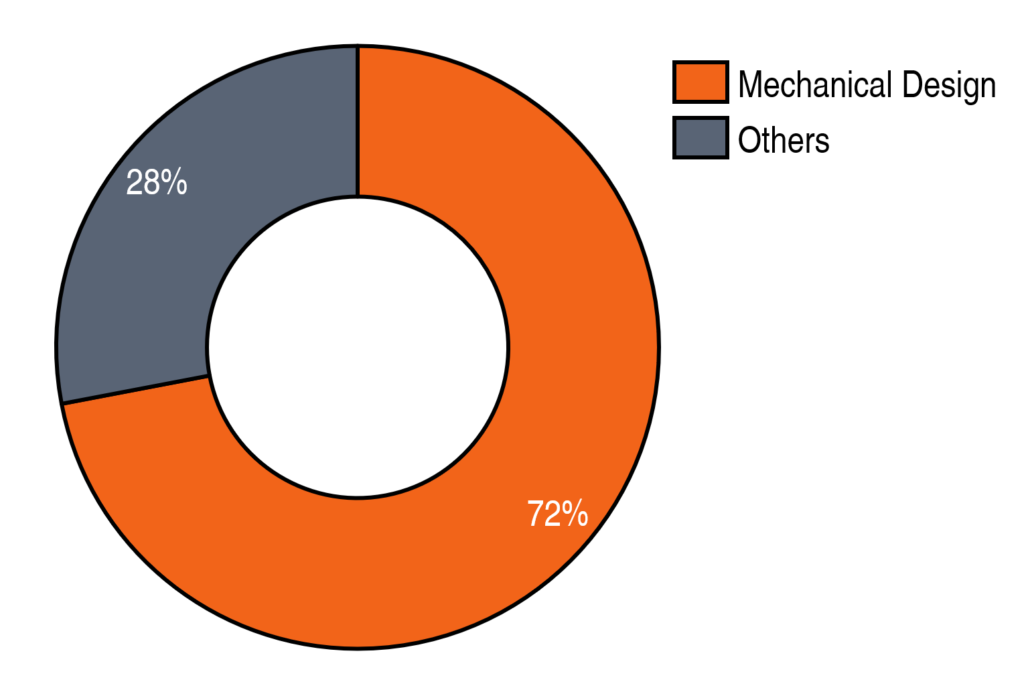

Right first time / time-to-quality

Ensuring a predictable robust design reduces the change of engineering detours and enables product professionals to achieve the right quality faster.

Root causes for product launch detours after design verification | divided into categories

Value engineering & cost reduction

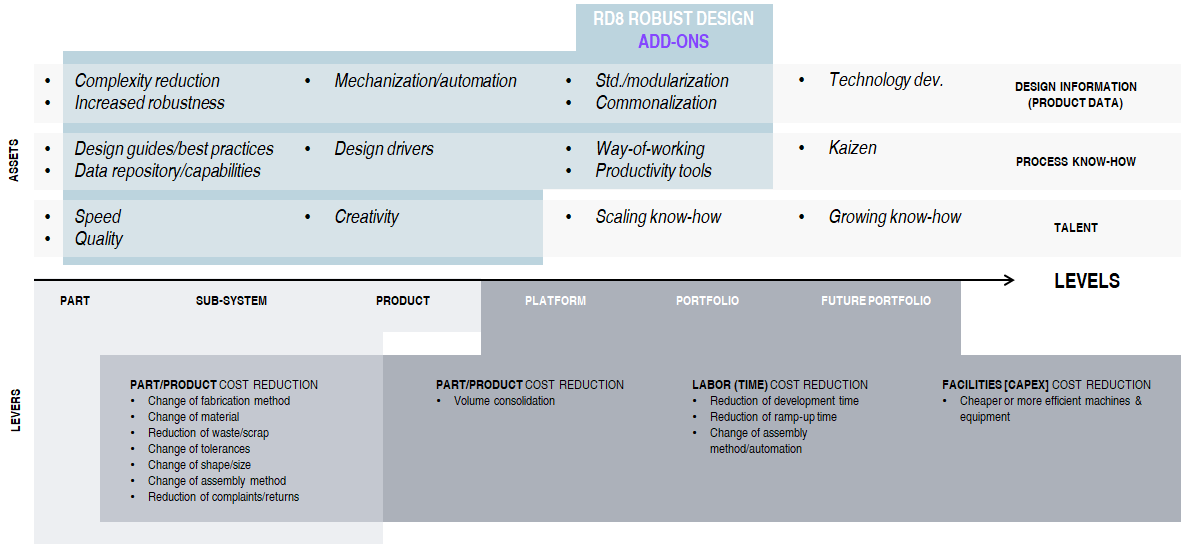

Value engineering and cost reduction strategies go hand-in-hand. Applying Robust Design as an add-on to the “ordinary” typically yields extraordinary results.

Mapping of how Robust Design boosts cost reduction efforts

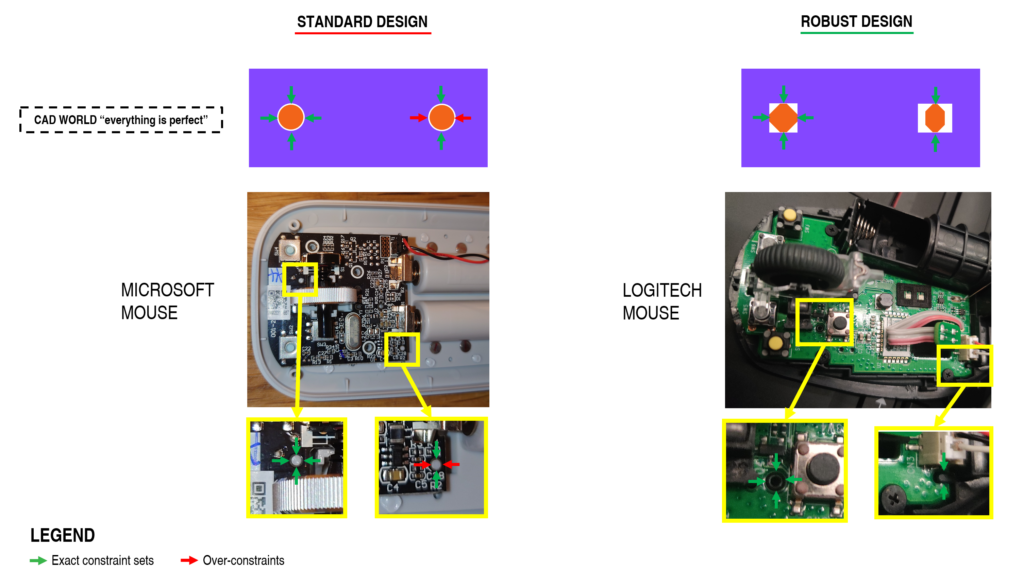

EXAMPLE | Kinematic design: interface design

Mechanical engineering: a basic example and illustration of a standard design and a robust design. Illustrated by the interface by two components (in a 2D cross-section); purple and orange.

The illustration below shows two designs:

- Standard design

- Robust Design

And two scenarios:

- CAD WORLD “everything is perfect”

- PRODUCTION “variation exists”

Mechanical product development: a standard design is often based on what is easy to sketch/create in 3D CAD systems and what looks nice to the eye (e.g. symmetry and patterns). In a 3D CAD system, everything is perfect! A Robust Design on the other hand is a design that is optimized to handle variation.

STANDARD DESIGN

In the example, the “STANDARD DESIGN” looks fine in the “CAD WORLD” scenario. In the “PRODUCTION” scenario variation is simulated by simulating a variation in the distance between the two positioning features (orange features). The consequence of the variation is a part-part collision. The impact of this collision needs to be verified or could be seen as negative design profit (additional engineering is needed, extra material or requirements needs to be considered, extra requirements to production/assembly, poor impact on customer value, ….) and is hence noted as a drop in quality.

ROBUST DESIGN

The exact same variation between the positioning features (orange features) is simulated in the ROBUST DESIGN example. The variation, in this case, does not result in a collision and hence there is no drop in design profit and/or quality.

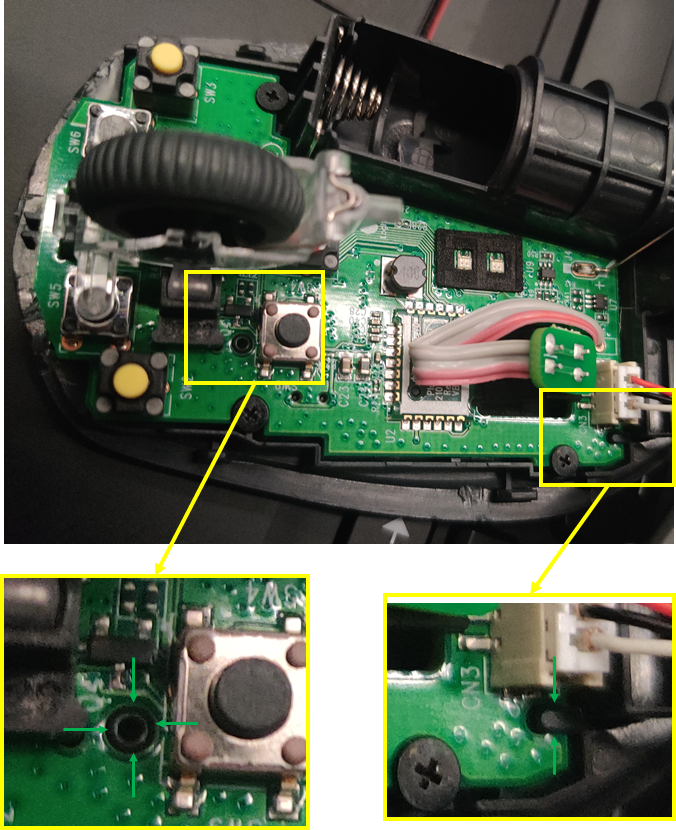

REAL LIFE ROBUST DESIGN EXAMPLE: a Microsoft vs. Logitech mouse (PCB interfaces)

In the example below two different products are shown.

- A Microsoft mouse

- A Logitech mouse

The focus of this example for both products is the interface between the “housing” plastic part and the PCB part.

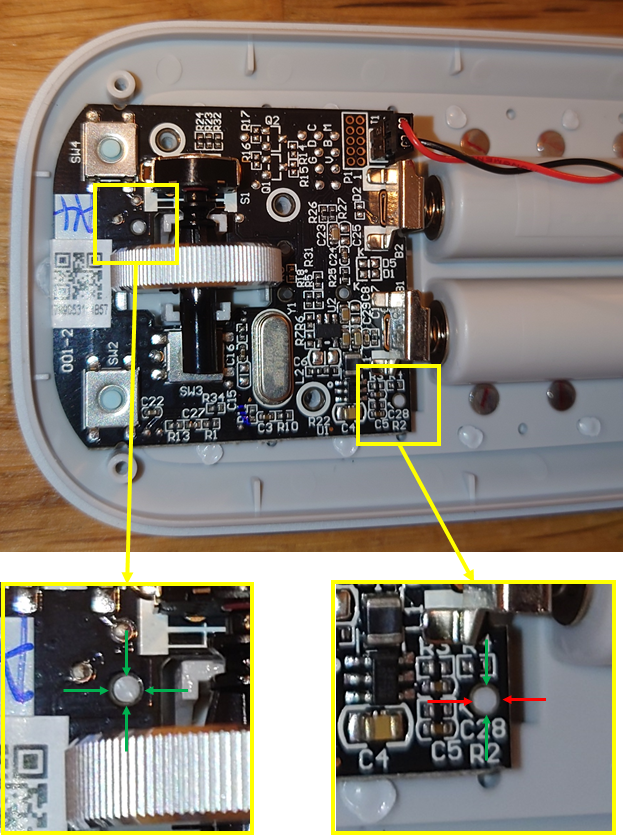

The Microsoft mouse is 1-1 with the “STANDARD DESIGN” example. This is denoted by the legend with the exact constraint set and the over-constraints. Learn more about interface design here or through RD8 training courses.

The Logitech mouse: the PCB is positioned by a “positioning pin” and a “second pin” where there is intentionally added the needed clearance to accommodate for expected variation between the pins – hence making the interface robust.

Close ups

Microsoft Mouse – look inside

Logitech Mouse – look inside

Robust Design background

Mobility & kinematic design

In RD8 tools & systems, we use Kutzbach’s modification of Gruebler’s mobility equation as a foundation for the mobility equation. Moreover, the equations link to many names. Also, Russian mathematician Pafnuty Chebyshevs’s name is often linked to the formula – read more at Wikipedia here. The notion of mobility is used in Robust Design to describe systems kinematic design1. Making a high-performing kinematic system implies that the system (a mechanism) should be ideally constrained, resulting in ideal mobility. On the detailed design level (interface design) the Robust Design principle builds upon “constraint theory” / “exact constraint design”.

Robust Design & Six Sigma

People often use Six Sigma as a quality standard when talking about process capabilities and derives from the statistical world. “The name ‘Six Sigma’ derives from statistical terminology; Sigma (σ) means standard deviation. For a normal distribution, the probability of falling within a ±6 sigma range around the mean is 0.9999966. In a production process, the ‘Six Sigma standard’ means that the defect rate of the process will be 3.4 defects per million units.”2

Taguchi methods

Robust Design’s background originated from various methods of optimizing product quality, mainly from Taguchi methods (quality improvement approaches developed by Genichi Taguchi). Taguchi methods are a part of the Six Sigma framework – one of the largest business management systems today. Something that has improved processes and saved billions of dollars for companies. In Six Sigma, one of the main objectives is “to increase performance and decrease performance variation”3 in a process. A process can be a service- or a product process, e.g., a production process or a billing process. RD8’s focus is on the design of robust physical products – not services.

"If you recognize over-constraint when the problem first presents, or better yet, apply exact constraint during initial design, you will avoid altogether the alltoo-common characteristic spiral: stiffening parts, tightening tolerances, and fighting assembly troubles."

James G. Skakoon - Author: The Elements of Mechanical Design; published by ASME Press

Taguchi states that “any deviation from a design objective constitutes a loss in quality”4. Furthermore, he states that it reflects a financial loss due to a potentially reduced product life, performance, and economy. In addition, the deviation of a design can influence the economy due to a loss in customer satisfaction, service and repair costs, market credibility, and a potential loss of market shares.

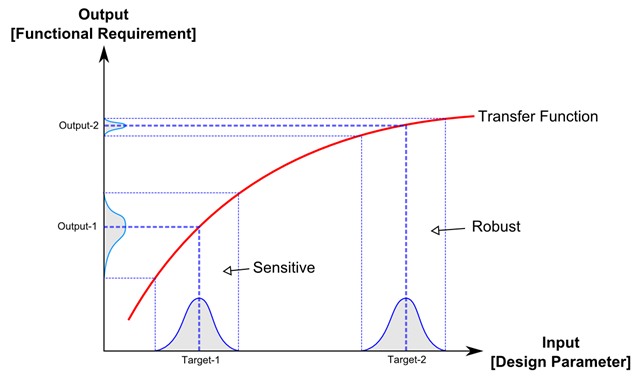

Taguchi defines the term robustness and describes it as a design with a functional output with minimal sensitivity to its input variations.

"Any deviation from a design objective constitutes a loss in quality"

Genichi Taguchi

- Input-output functions

- I/O functions

- Transfer functions

- Calculation models

When the transfer function is known, it can be analyzed and plotted on a graph. You can see an example in the illustration above. On the x-axis, the input or design parameter is given. On the y-axis, the output or functional requirement is given. A design parameter (e.g., a measure on a technical drawing) will have a tolerance, and in a production setting, the measure will fall out in some sort of distribution in this case. Assumed within the given tolerance as a normal distribution.

For the two different targets “Target-1” and “Target-2” in the illustration, it is seen that with the same distribution at “Target-1” and “Target-2”, the output is different. “Output-2” is much less than “Output-1”; thus, they are produced with the same tolerances. This is what defines if a function is sensitive or robust – as shown in the illustration.

Axiomatic design

Axiomatic design gets used to analyze the relations between a product’s functional requirements (FR) and its design parameters (DP). The goal is to lower the complexity of the product and ensure more control of the design, resulting in better performance.

As the market requests for new products increase and higher demands are set for frequency. Therefore there is a demand for fast product development of healthy designs. Meaning that the development “requires efficient and systematic procedures to analyze, synthesize, and validate conceived concepts upfront”5.

Nam Pyo Suh has developed the methods of axiomatic design since 1977, and the methods state two axioms: The independence axiom and The information axiom.

Axiom 1 | The independence axiom

Maintain the independence of the functional requirements.

Axiom 1 is about decoupling functional requirements and making them independent from each other. This is done by decoupling the design parameters of the functional requirements. A typical example is a water hose which has two functions: temperature and flow. Some designs change the flow whenever you want to adjust the temperature – this is a coupled system. If you follow axiom 1, you decouple the two functions (as seen in some designs) where temperature-function and flow-function are separated. These principles are, e.g., reflected in practice in the RD8 interface rules – to ensure functional surfaces in an interface have the ideal amount of information.

Axiom 2 | The Information Axiom

Minimize the information content in a design.

Axiom 2 has to do with the complexity of the design and is related to the theory of Taguchi. It is based on the probability of successful manufacturing of a design. If you lower the complexity of a design, you are more likely to hit the target and drop the product’s quality. Complexity is related to minimizing information – in practice – reducing the number of constraints in a system. This reflects in the RD8 interface rules and mobility theory.

References

1) CHRISTENSEN, M.E., HOWARD, T.J. and RASMUSSEN, J.J., 2012. The Foundation for Robust Design: Enabling Robustness Through Kinematic Design and Design Clarity

2) KAI YANG, B.E., 2003. Design for Six Sigma: A Roadmap for Product Development. United States of America: McGraw-Hill, p.21

3) Kai Yang 2003, Design for Six Sigma: A Roadmap for Product Development. United States of America: McGraw-Hill, p.21

4) KALPAKJIAN, S. and SCHMID, S.R., 2006. Manufacturing engineering and technology. Pearson/Prentice Hall., p.1115

5) Kai Yang 2003, Design for Six Sigma: A Roadmap for Product Development. United States of America: McGraw-Hill, p.201

Are you interested in hearing more about

Robust Design & our engineering services?

Book a meeting with us already today